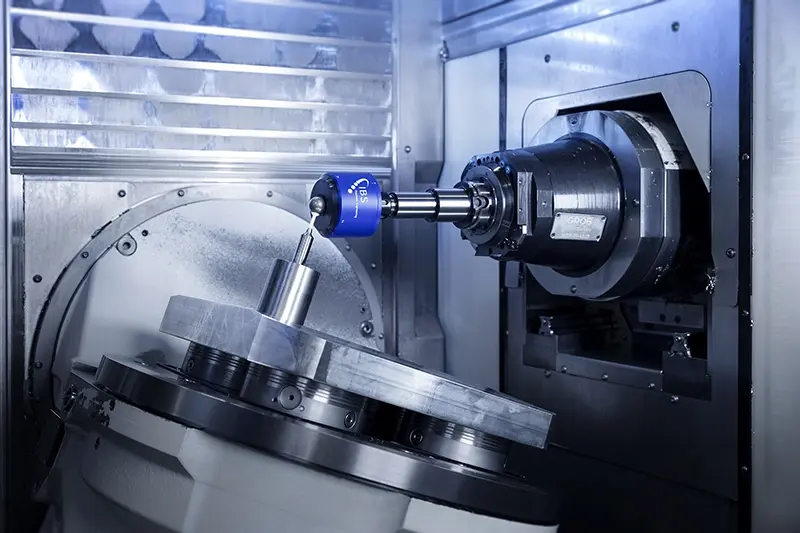

Last September IBS Precision Engineering conducted a three-day training of our Position Inspector, Rotary Inspector and Rotary Analyzer systems at the Polish company HTM. HTM is an exclusive distributor of machine tools and technologies, providing complex services for manufacturing companies in Poland. They ensure full service of machines, both during warranty period and after. Through our Polish agent Multisensor, the company bought these three measuring systems to calibrate and improve the overall performance of the CNC machine they supply to their customers.

A quick overview of the three systems:

The Position Inspector: The positioning accuracy of any machine tool is of vital importance. It governs how and when your end product is within tolerance and defines your productivity. Over time accuracy can fall off and with it, effective output. The Position Inspector measuring system delivers rapid and precise measurement for the positioning accuracy of your machine.

The Rotary Inspector: Qualifying the performance of 5-axis machines can be complex. The Rotary Inspector measurement system provides a revolutionary method to simplify this process; enabling rapid assessment and correction of the 5-axis kinematic performance.

The Rotary Analyzer: For comprehensive analysis and diagnostics of 5-axis machine tools, the Rotary Analyzer places full capability in your hands. Machine tool developers and professional maintenance providers can quantify 4- and 5-axis machine performance in real time with both static and dynamic measurement possible.

With an ultra-precision measurement now below 90 seconds, the uptime of the CNC machine has increased significantly. The systems provide peace of mind and control by guaranteeing the CNC machine is within specification and ensures rapid and automatic qualification of cutting position and rotary table characteristics.

With an ultra-precision measurement now below 90 seconds, the uptime of the CNC machine has increased significantly. The systems provide peace of mind and control by guaranteeing the CNC machine is within specification and ensures rapid and automatic qualification of cutting position and rotary table characteristics.

HTM believe it is very important that their service teams are fully trained and able to operate the ultra-precision measuring systems with trust and confidence. This video shows impressions of the training, comments of people involved, and the measuring systems in action.

Are you interested in increasing your own piece of mind and have ultra-high precision measurements of your machine tools? Send us a quick email and we will contact you.