- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

When you need in-depth analysis and diagnostics of your machine tool linear axes, the Position Analyzer provides the measurement capability you need. The system provides a simple but powerful principle to measure the machine’s 3D positioning and straightness errors according to ISO 230 plus much more.

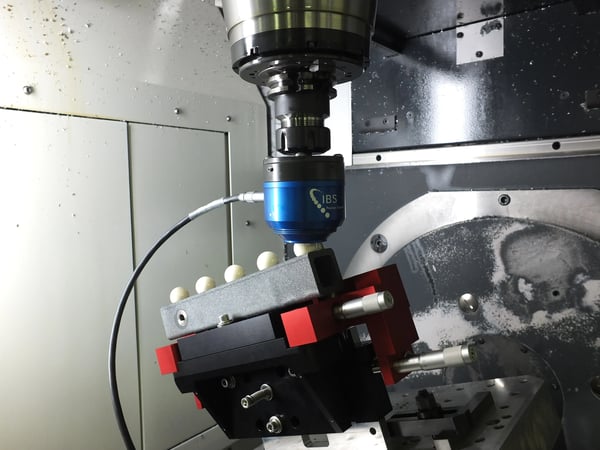

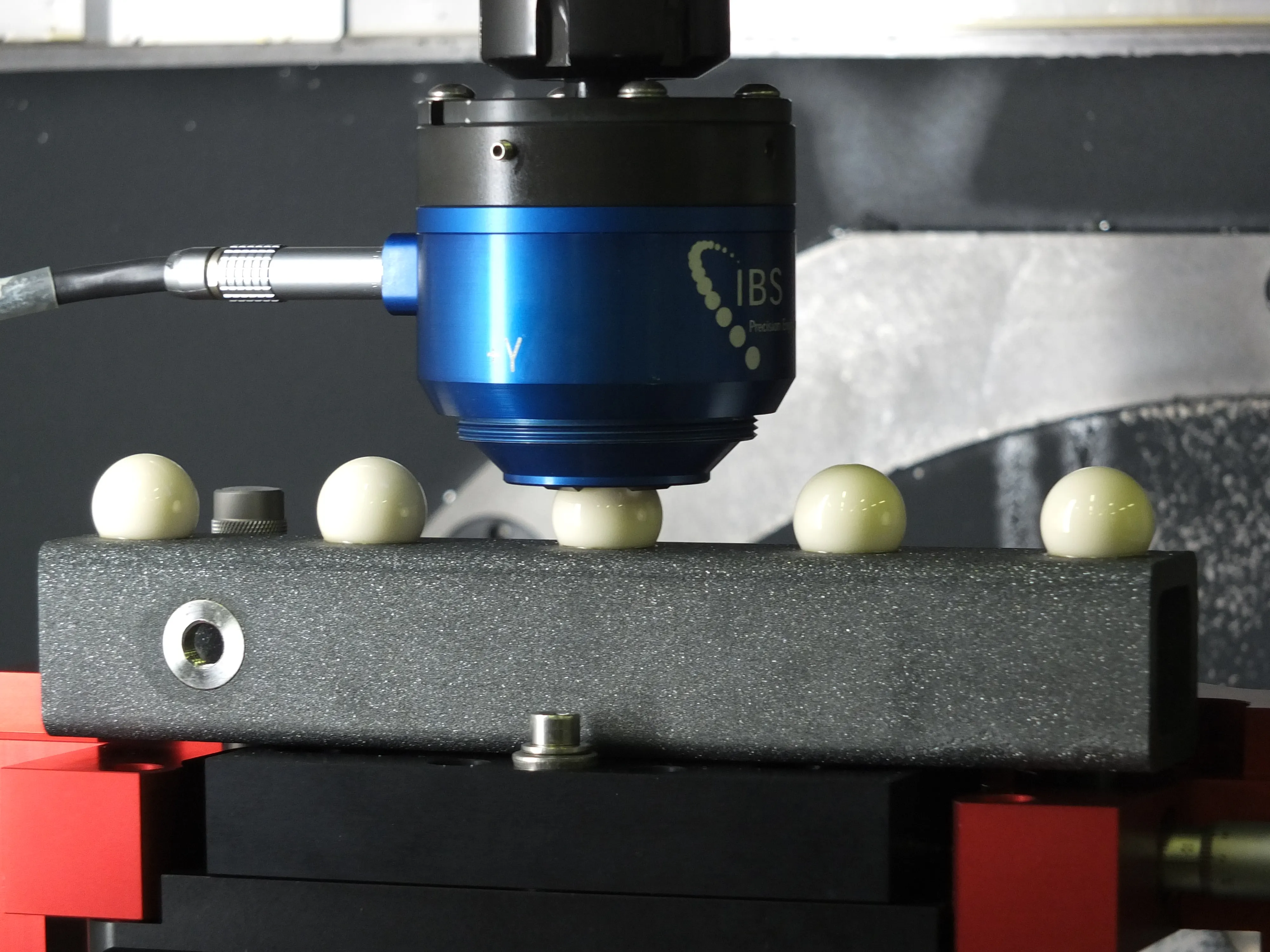

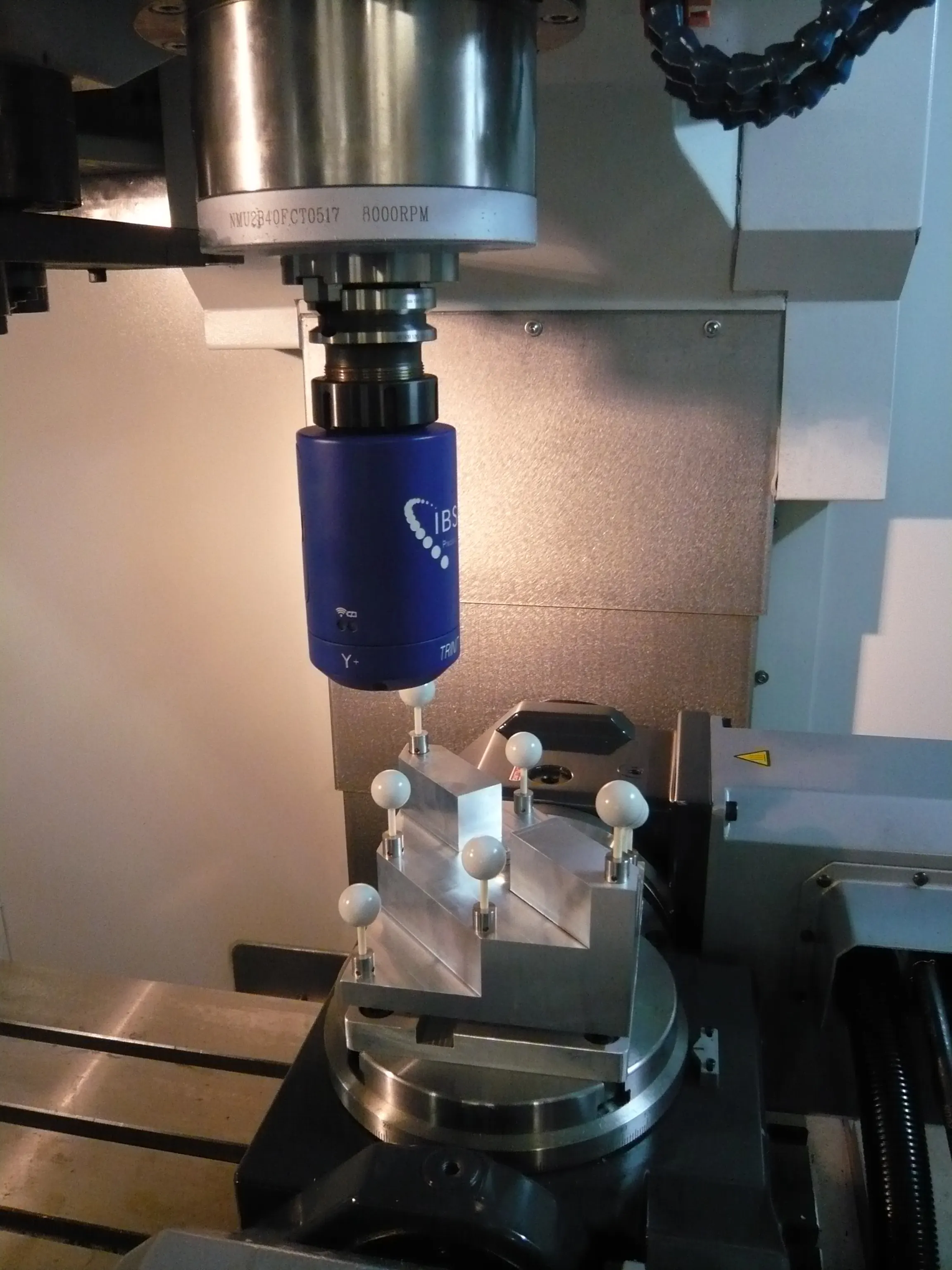

The Position Analyzer consists of a ball beam artefact that is placed on the machine table and a wireless measurement probe that is inserted in the spindle. The artefact contains a line of balls whose position is known with sub-micron accuracy. Alternatively, custom made artefacts can be delivered for specific machine applications. The artefact may be positioned in any orientation within the machine. The machine is commanded to move the probe to each of the balls in a sequence defined by the user. The probe measures the error that occurs in positioning of the probe in X, Y and Z directions, and calculates the linear axes errors according to the test defined.

Position Analyzer ball beams:

A range of standard ball beams is available for the Position Analyzer. Alternatively artefacts can be made to order. The standard ball beam is constructed from 22 mm diameter precision balls. The number and spacing of the precision balls can be chosen according to the application.

Provided in the Position Analyzer kit:

The Position Analyzer kit includes a wireless Trinity probe plus battery charger. A calibrated artefact is supplied with calibration certificate, plus mounting accessories. The probe and artefact are supplied in a travel case. The Position Analyzer Software App is included.

The Position Analyzer was designed as a sister product to the Position Inspector, for applications where machine size or layout requires a specially defined measurement artefact.

The Position Analyzer offers all the advantages of rapid measurement and sub-micron accuracy, similar to the Position Inspector. However the use of alternative artefacts and orientations allows for unique machine measurements. The system provides a simple but powerful principle to measure the machine’s 3D positioning and straightness errors according to ISO 230 plus much more with comprehensive diagnostic capability. A large probe range enables simple set-up without the need for complex alignment procedures. Artefact measurement is completed in minutes.

Unique strengths of the Position Analyzer: