- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

For extremely accurate linear or rotary motion, flat air bearings are the ideal components. They offer a non-contact, frictionless bearing solution with zero wear.

Our engineers can guide you on the right component for your application.

Air bearings are tested by our expert measurement team.

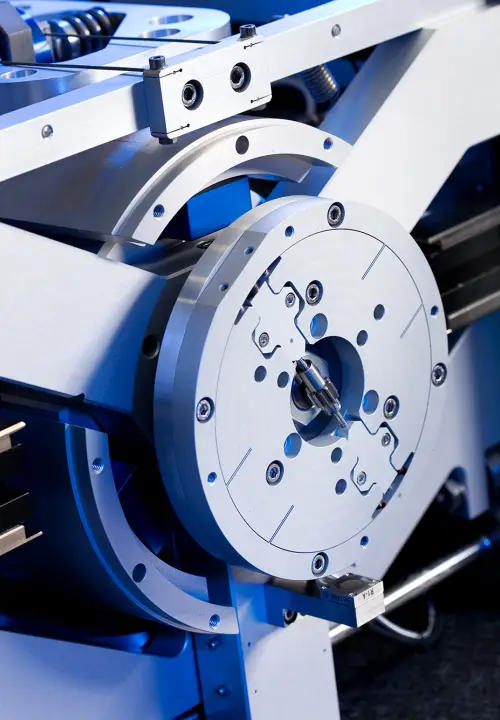

Solutions designed for your application.

Whether your challenge is precision, speed or environment, we can offer unmatched experience.

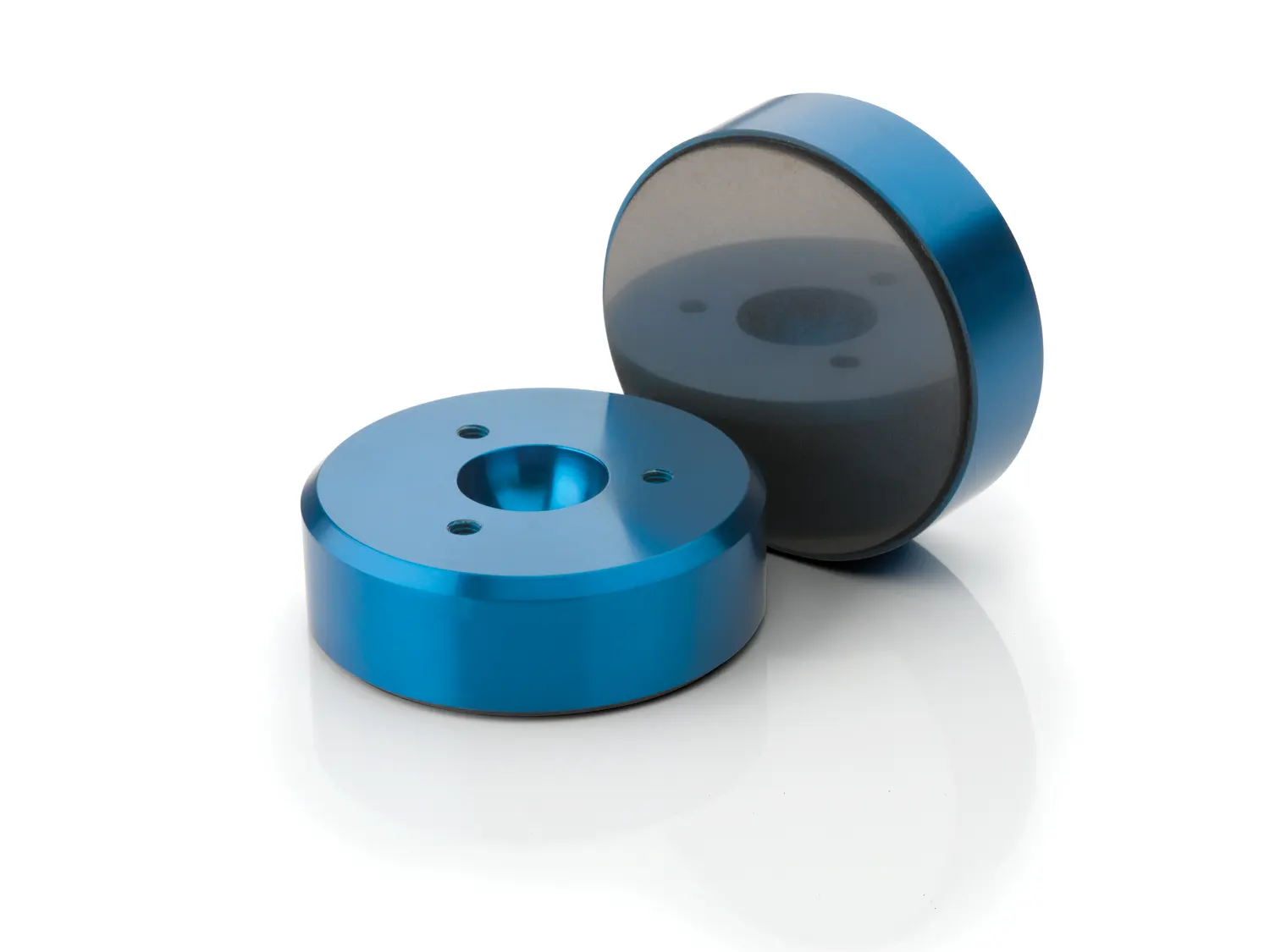

Our Flat Air Bearings were the original standard, off the shelf, Porous Media Air Bearing product line. These versatile Air Bearings are available in round or rectangular configurations, ideal for frictionless motion control in a wide array of applications.

Flat Round Porous Media Air Bearings allow anyone to design and build their own custom Air Bearing assemblies. The round configuration makes the most efficient use of standard raw materials and ultra-precision manufacturing techniques, ensuring low cost standard product availability. In addition to the standard product line (shown), custom Flat Round Air Bearings are also available.

Flat Rectangular Air Bearings are designed to carry high loads while maximizing the load bearing surface through a gimballed mounting system. These Air Bearings can be mounted on ball mounts, providing a self-levelling interface between the Air Bearing and the guide surface. For some linear applications, the rectangular profile provides a more efficient bearing surface alignment.

mm

Standard flat air bearings are designed for environments up to 50°C but are mostly used at room temperature of approximately 20°C. In terms of speed, they can support linear speeds exceeding 50 m/s, depending on load, air supply and surface finish. Custom made air bearings have more possibilities and can be designed to your specific application. For example, extreme temperatures up to 250°C or high accelerations up to 100 G.

Are you wondering if your conditions are suitable for flat air bearings? We can help you choose the right flat air bearing. Feel free to contact us straight away.

The load capacity for our flat air bearings depends on the size, but can vary from 50N to 20kN. In porous media flat air bearings, the pressure under the bearing is very evenly distributed. Load capacity is determined by:

Load Capacity = Surface Area x Input Pressure x Efficiency

(where the efficiency can be approximated to 50% for indication)

Flat bearings have the highest load capacity of our product range. Check the bearing specification sheet for the load capacity. Are you wondering if your application is suitable for flat air bearings? We can help you choose the right flat air bearing. Feel free to contact us straight away.

Flat air bearings are a natural choice over rolling element bearings for applications requiring a combination of high speed, repeatable motion. The main advantages to flat air bearings are:

Are you wondering if we can replace your traditional bearing for air bearings? Feel free to contact us straight away.

As for regular air bearings, flat and smooth guide surfaces with a suggested finish of 0.4 Ra in µm are required for optimal performance of flat air bearings. Common surface materials are:

Are you wondering if your conditions are suitable for flat air bearings? We can help you choose the right flat air bearing. Feel free to contact us straight away.

Flat air bearings require:

Oil-free compressors or centralized industrial air systems are common sources for good quality air supply.

More detailed information about the air supply is explained on our operation, cleaning and care page.

Are you wondering if your conditions are suitable for flat air bearings? We can help you choose the right flat air bearing. Feel free to contact us straight away.

More questions? Read more Air Bearings FAQ's