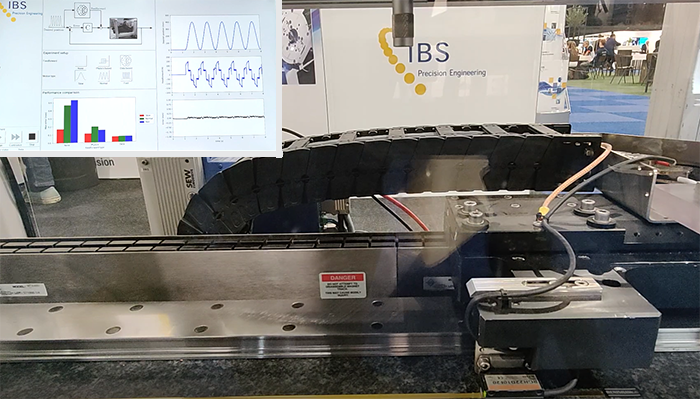

Physics guided neural network feedforward control

Performance of model–based feedforward controllers is typically limited by the accuracy of the inverse system dynamics model. Physics guided neural network(PGNN) feedforward control proposes a general framework for inversion–based feedforward controller design.