- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

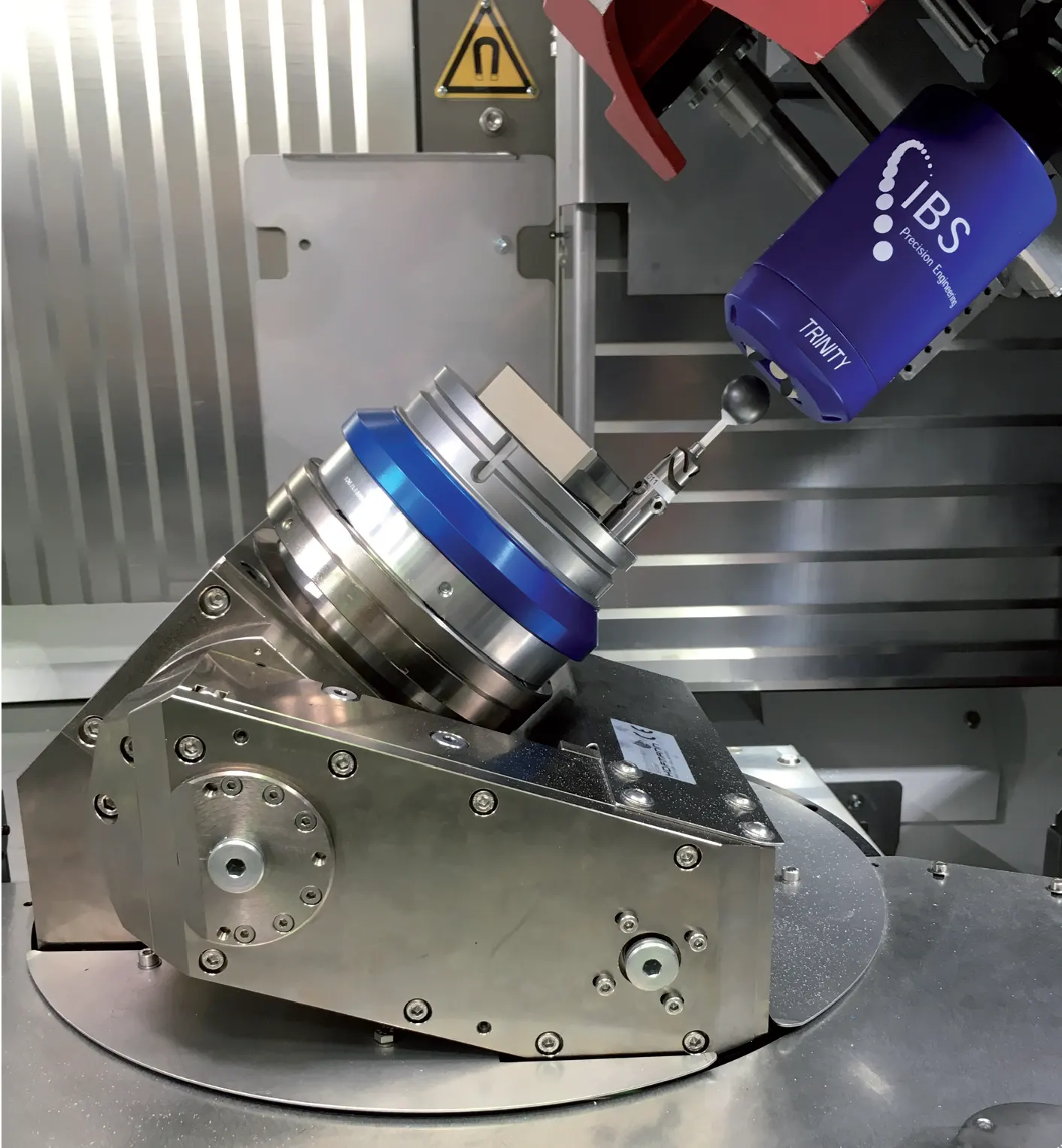

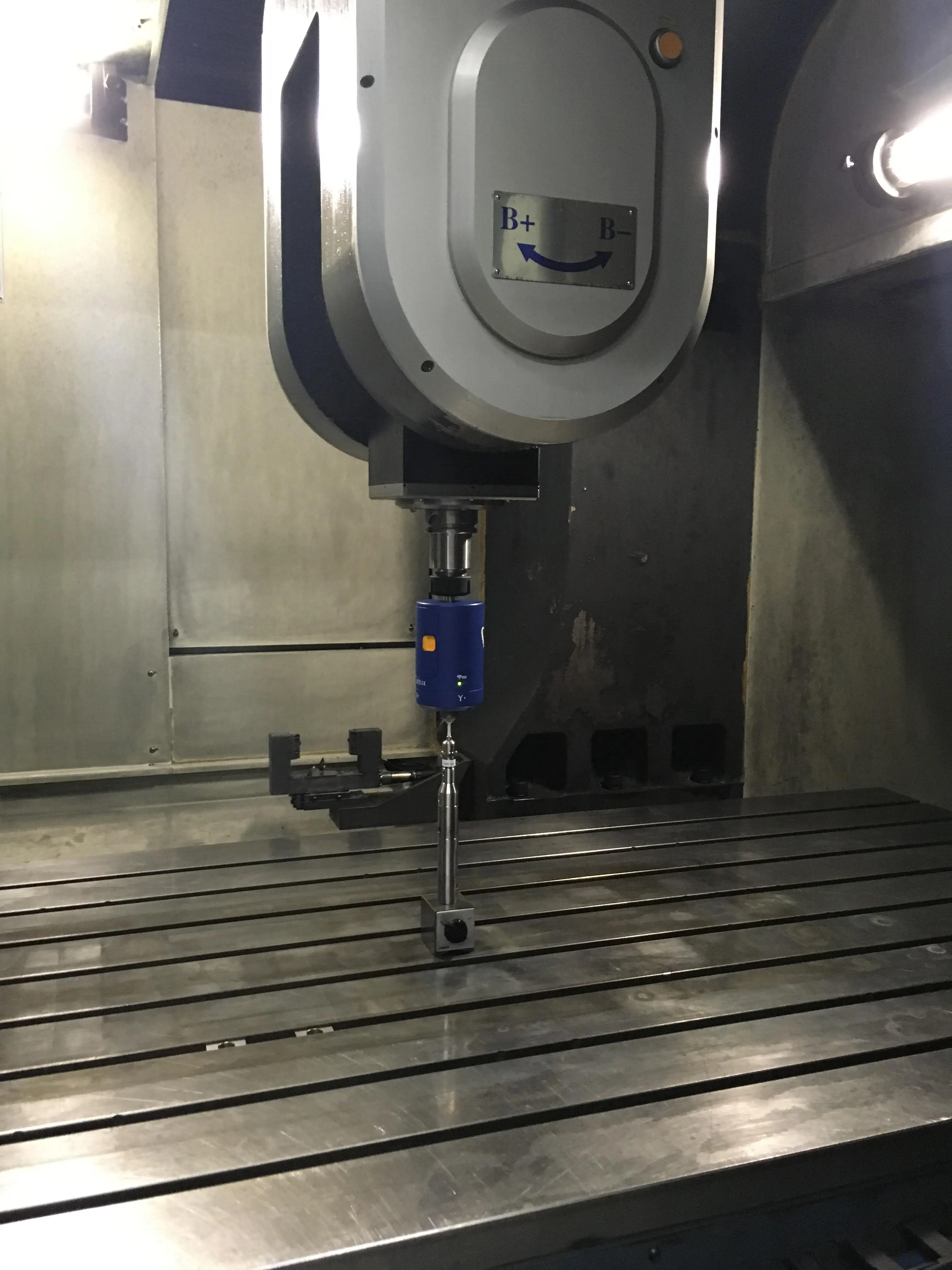

For comprehensive analysis and diagnostics of 5-axis machine tools, the Rotary Analyzer places full capability in your hands. Machine tool developers and professional maintenance providers can quantify 4- and 5-axis machine performance in real time with both static and dynamic measurement possible.

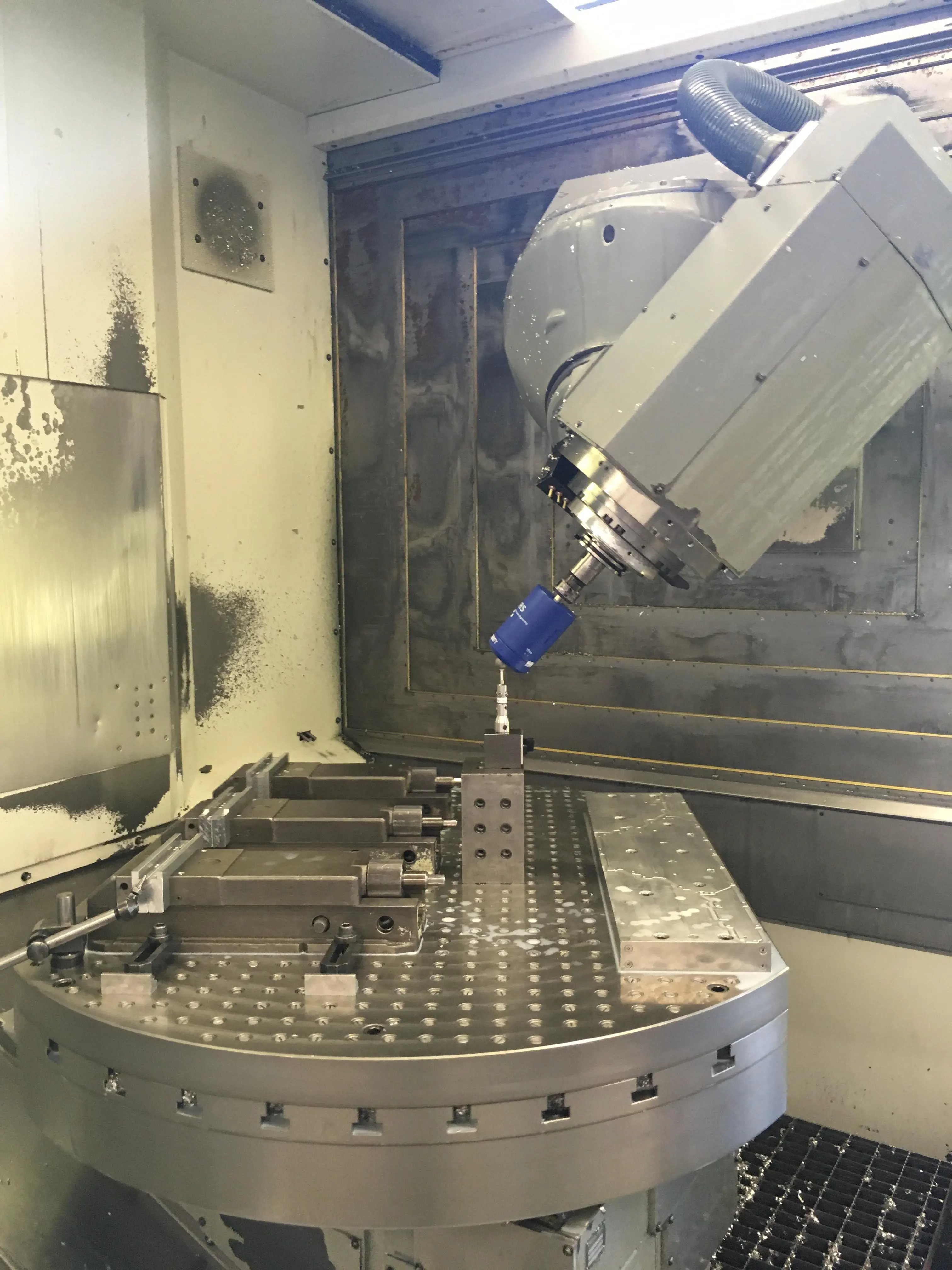

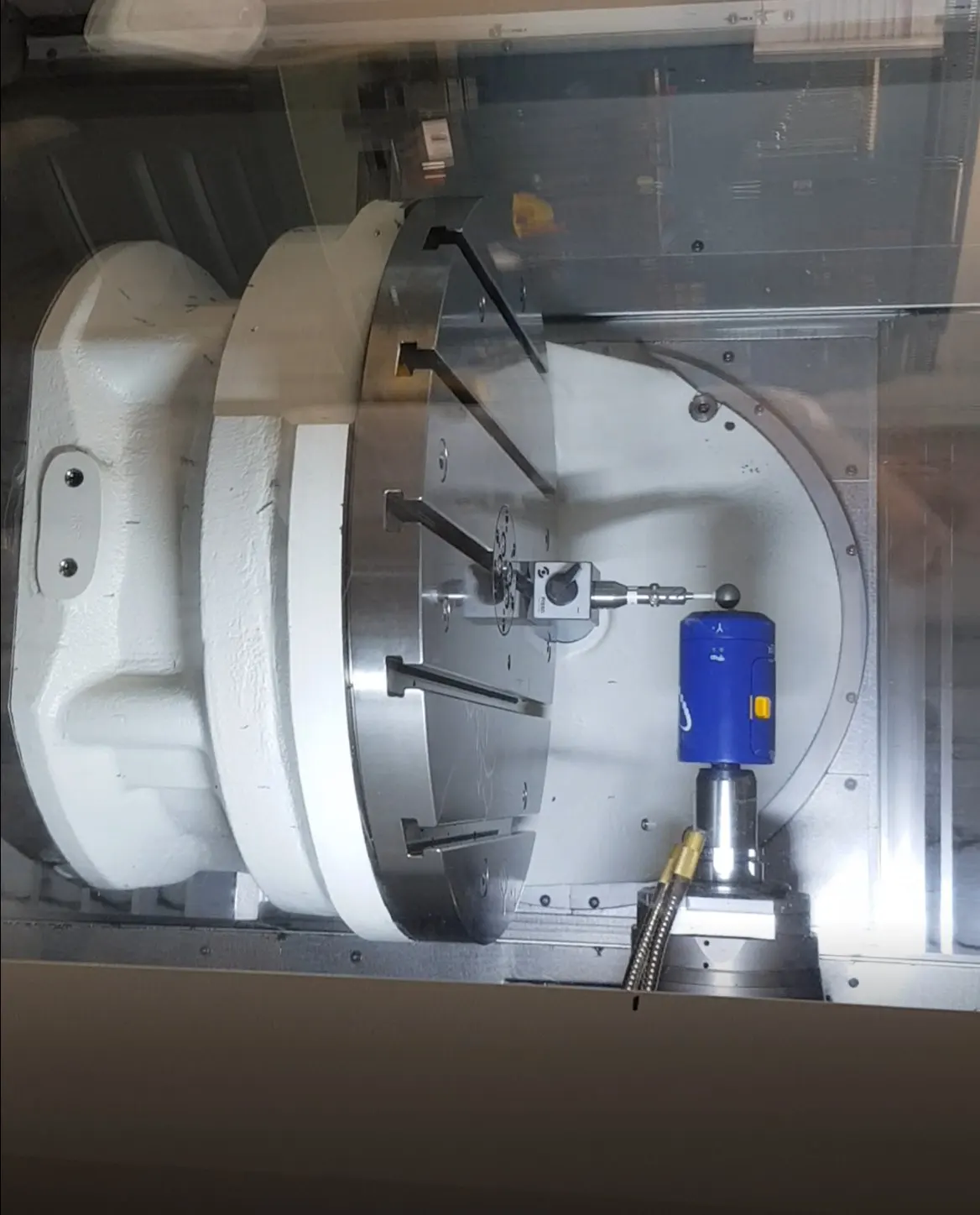

The Rotary Analyzer consists of a master ball that is placed on the machine table and a wireless measurement probe inserted in the spindle. The machine is commanded to complete a user defined 3-, 4- or 5-axis test. Like the Rotary Inspector the path of the probe, representing the Tool Centre Point (TCP), is measured relative to the master ball, representing the workpiece. In this way the errors in the cutting path are directly measured and visualized in X, Y and Z directions. The master ball can be pallet mounted and the probe placed in the toolchain.

Provided in the Rotary Analyzer kit:

The Rotary Analyzer kit includes a wireless Trinity probe plus battery charger, master ball and mounting accessories plus travel case. The Rotary Analyzer Software App is included.

The Rotary Analyzer was designed as a sister product to the Rotary Inspector, for applications where machine specific tests and in-depth analysis are wanted. The Rotary Analyzer offers all the advantages of rapid measurement and sub-micron accuracy of the Rotary Inspector.

The Rotary Analyzer App can be easily programmed to perform a range of user defined tests including ISO standard measurements. Both static and dynamic tests can be performed and a suite of analysis options allows for in-depth characterisation of the machine tool performance. Machine tool developers and professional maintenance providers can quantify multi-axis machine performance in real time. Customised machine acceptance tests can be developed and measurements completed in minutes.

Unique strengths of the Rotary Analyzer:

' I'm a big fan of the probe.... it will be an excellent tool to put into production. Calibration of our 3 axis rotary table would have simply been impossible without it.'