- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

When you need state-of-the-art precision in 3D surface coordinate measurement.

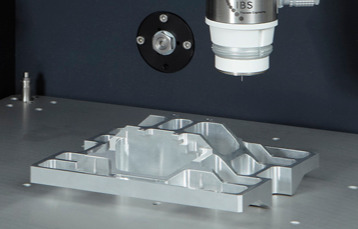

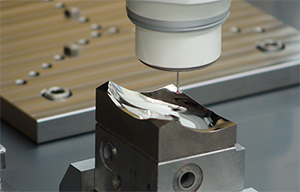

When you need a measurement system for large and complex parts, that delivers nanometer accuracy in all three dimensions, ISARA 400 offers a state-of-the-art solution. As an ultra precision co-ordinate measuring machine, it defines the standard for a generation.

Based on core precision engineering principles, with the ISARA 400 you can benefit from design which overcomes the limitations of standard optical methods or contacting profilers, making it the most accurate three-dimensional coordinate measuring machine available on the market.

With an unprecedented ratio of measurement volume to measurement accuracy, its ground breaking approach allows you to redefine what is possible in measurement. Time after time, in tests set by leading measurement institutes, ISARA 400 has proven to be the only machine able to offer traceable full 3D measurement of freeforms, aspheres and more challenging parts.

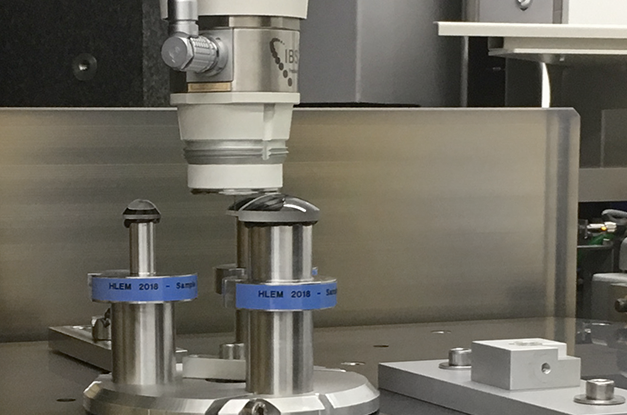

To achieve its leading performance ISARA400 is designed according to several important principles. To avoid parallax errors, a measuring system must be placed coaxially with the axis along which displacements are to be measured. This is known as the Abbe principle. In the ISARA concept, the Abbe principle is fulfilled in all three coordinate axes over the entire measuring volume.

In a measurement machine, the requirements for the measurement and structural functions are completely different. The ISARA400 CMM is able to reach a measurement uncertainty in the nanometre range by applying different frames to perform these functions. A further very important design aspect of ISARA is the ability to calibrate the measurement loop on the machine itself. Full traceability to international standards means that the measurement results are independently verifiable.

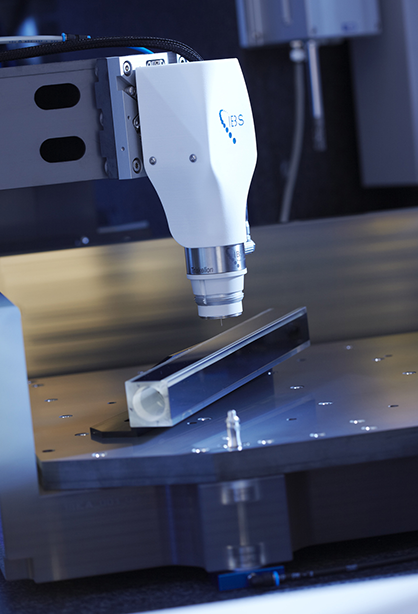

In general, thermal effects are among the largest sources of non-repeatability in measuring machine accuracy. The ISARA400 CMM minimizes these effects by making use of low-expansion materials such as Zerodur® and Silicon Carbide (SiC). During measurement, an enclosure minimizes heat input from the environment of the machine (e.g. operators). Thanks to an optimized design, the ISARA 3D CMM is able to reduce its thermal sensitivity to the nanometre level.