- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

Dynamics is a fundamental competence within IBS, woven into our daily engineering work and applied throughout the development of high-precision machines and instruments. Drawing from decades of experience as a machine builder, we have created a qualified Dynamics Toolbox that captures and standardizes our expertise.

The dynamic toolbox allows us to model dynamic behaviour early in the design process, using software models that are continuously validated against measurements on actual hardware. As a result, we can predict 80–90% of the key contributors to dynamic behaviour long before detailed engineering begins, enabling smarter architectural decisions, fewer redesign loops and shorter lead times.

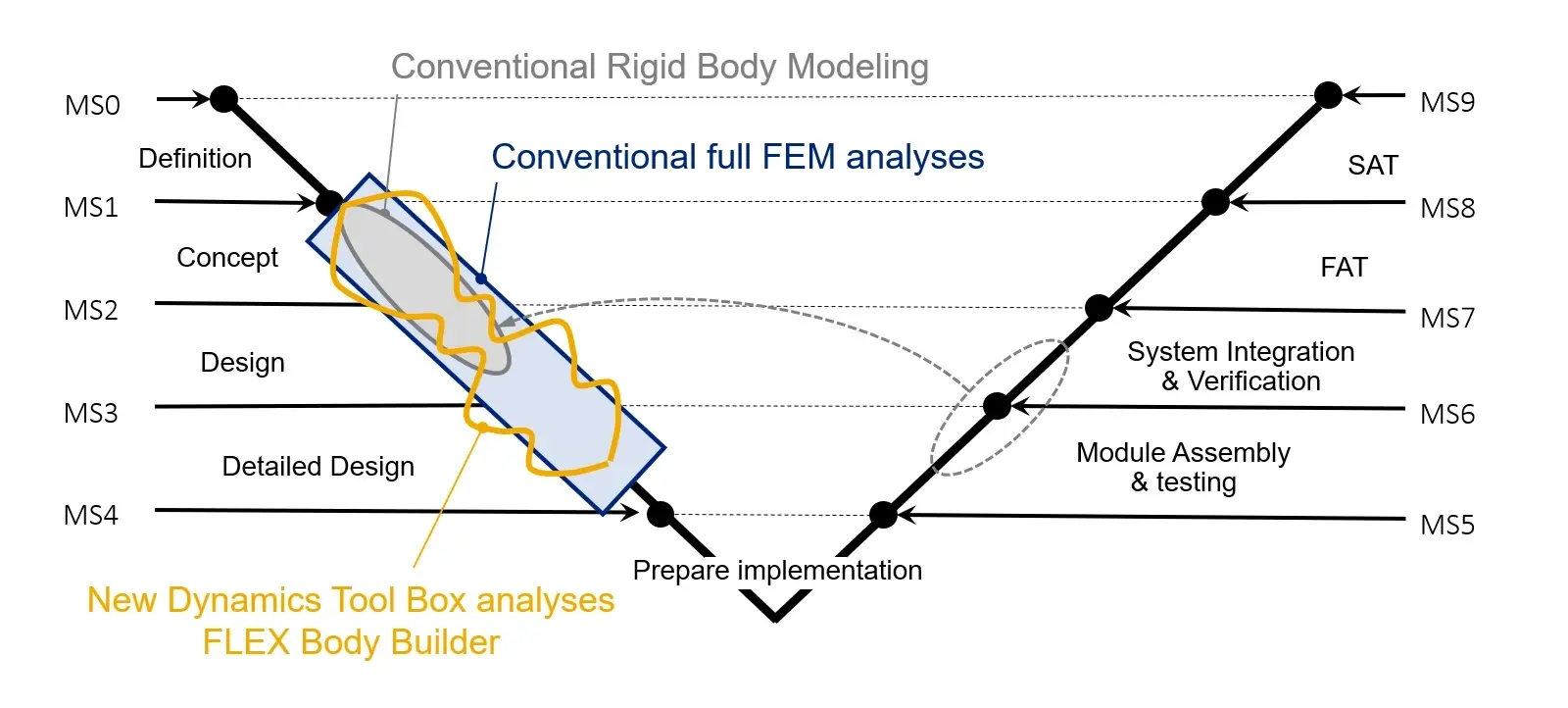

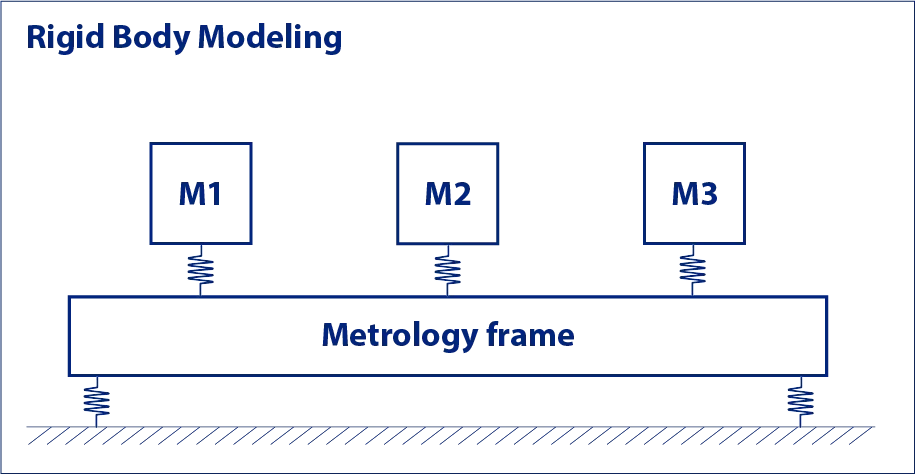

In conventional machine design, two approaches are commonly used. The first relies on rigid body modelling, which is fast and efficient in the early phases but carries a significant risk: dynamic effects and structural flexibility are often underestimated, leading to costly corrections during the build and commissioning phases. As a result, total project time and cost frequently exceed initial expectations.

The second conventional approach uses full Finite Element Method (FEM) analyses, offering high detail and low technical risk, but at the expense of long design cycles and substantial effort early on. This method can also create overreliance on local accuracy, while system-level behaviour receives less attention.

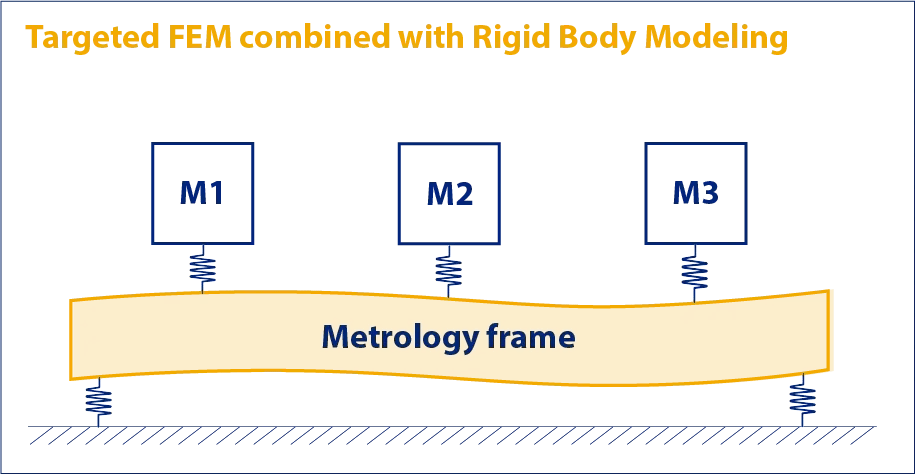

The new Dynamics Toolbox method bridges these extremes by combining speed with insight: it allows fast system-level modelling where possible, adds detailed flexibility only where needed and keeps a full-system model available throughout the process, resulting in the lowest overall lead time and total cost.

Our method combines practical measurement insights with efficient modelling techniques such as rigid body and flex body analysis, targeted FEM modelling of only the relevant elements and on-site quantification of external disturbances. Because we know from experience what truly influences machine behaviour, we avoid unnecessary complexity and focus on what delivers the highest impact. This approach ensures that our predictions are not only accurate but also cost-effective, reducing the overall cost of precision.

The IBS Dynamics Toolbox combines software and hardware tools into one validated and practice-proven approach. On the software side, the toolbox includes the FLEX Body Builder, which connects detailed local FEM analyses with full-system rigid body models to efficiently capture the most relevant dynamic contributions.

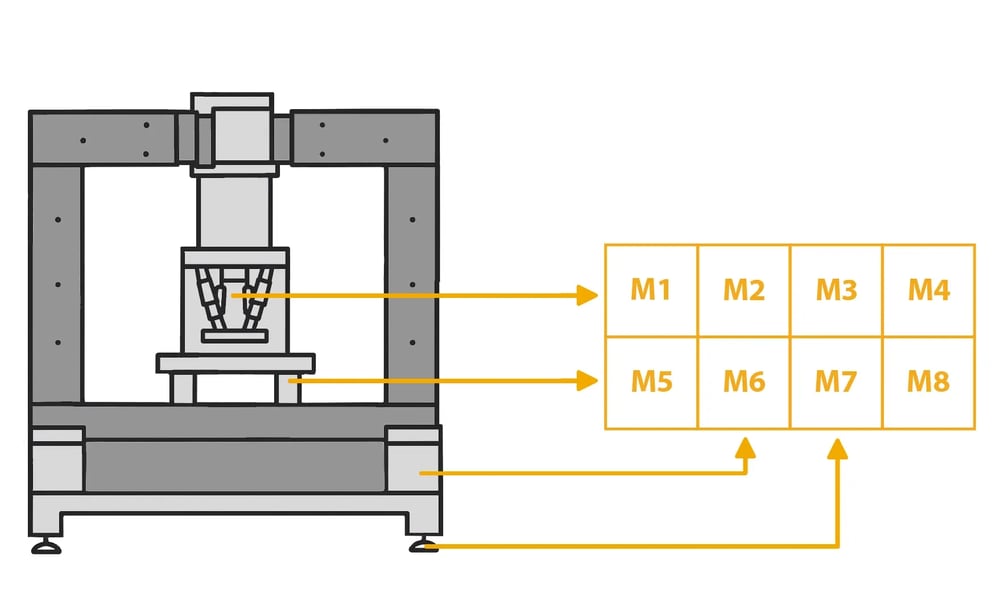

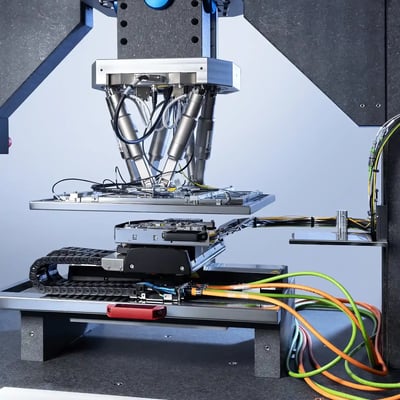

On the hardware side, the toolbox supports system-level dynamics analyses, including floor vibration measurements and root-cause investigations of unexpected machine behaviour. Both the software and hardware components have been developed, validated and proven in real engineering projects and on machines built by IBS.

We apply our Dynamics capability both to new machine development and to customers who need support with dynamic issues in existing systems. For new builds, our dynamics knowledge helps us determine the most effective architecture early in the project. For existing machines, we use the same toolbox to analyse performance, measure external disturbance, identify the true sources of dynamic problems and help to address these problems.

Our dynamics capability is integrated deeply into our engineering services. It enhances the quality, speed and predictability of our development projects and offers our customers a reliable, proven way to understand and improve dynamic behaviour in their systems.