- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

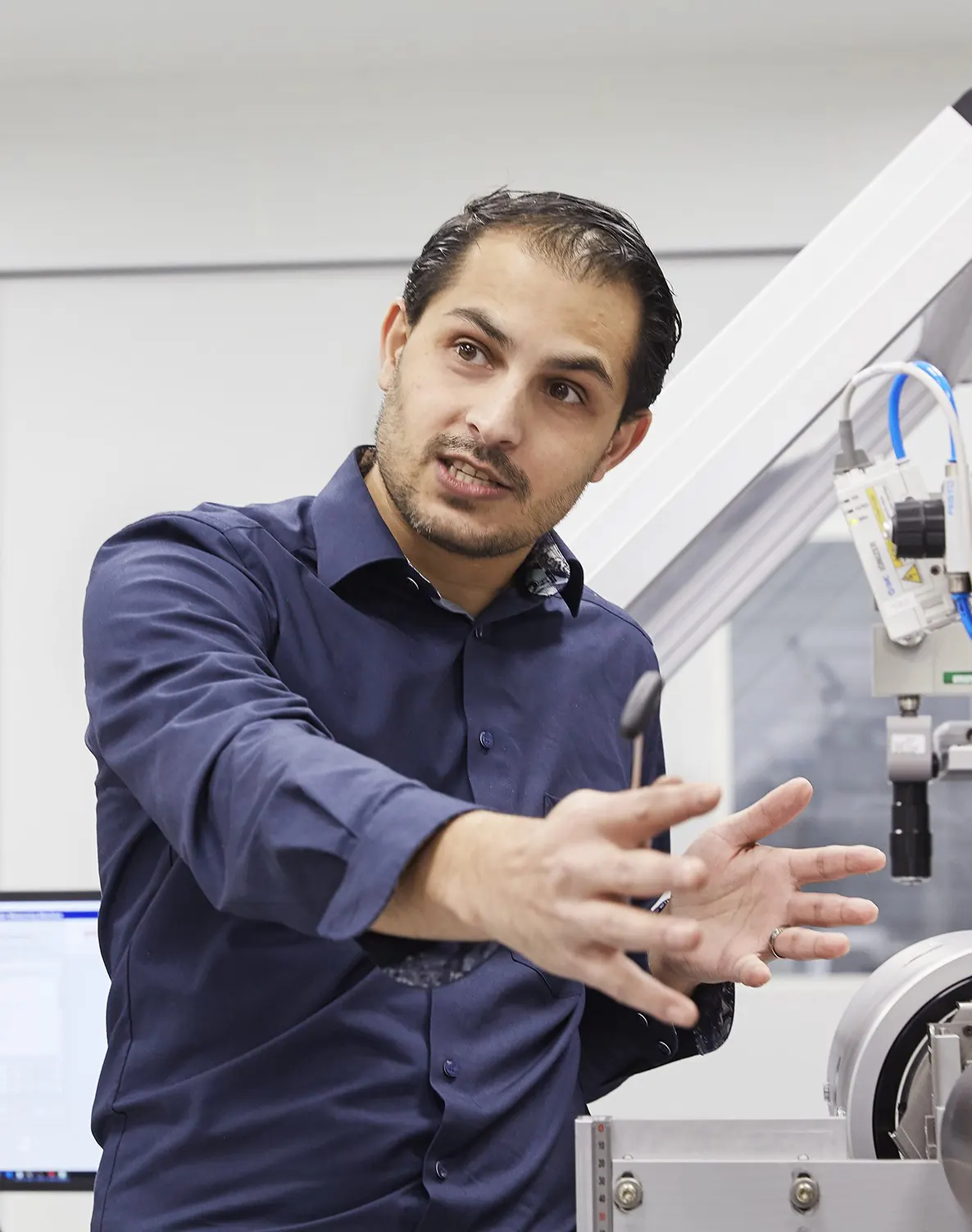

For frictionless rotary motion, these porous media air bearings are the ideal component. They offer high speed, high precision and no wear.

Our engineers can guide you on the right component for your application.

Air bearings are tested by our expert measurement team.

Solutions designed for your application.

Whether your challenge is precision, speed or environment, we can offer unmatched experience.

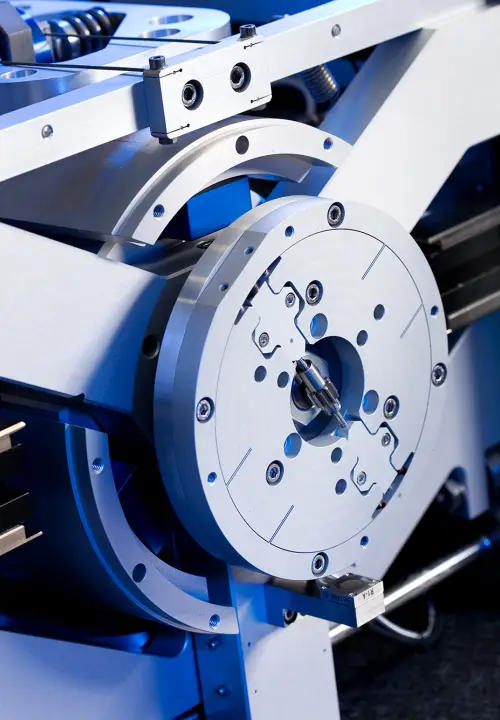

Radial Air Bearings are the ideal component for building frictionless rotary motion. These air bearings provide a fast, made-to-order solution. In either concave or convex configurations, the air bearings are ideal for a range of rotary applications, giving you all the differential advantages of air bearings that you require: high speed, high precision, no friction, no wear, no need for lubrication, excellent velocity control, and no noise.

Radial Air Bearings – Concave

Our Concave Radial Air Bearings are configured to ride along the outer diameter (OD) of your rotating artefact. Concave Air Bearings are designed to support the rotating artefact from the outside.

Radial Air Bearings – Convex

Like its Concave counterpart, our Convex Air Bearings are configured to ride on the inner diameter (ID) of your rotating artefact. The key difference is that Convex Air Bearings are designed to support the rotating artefact from the inside, as opposed to Concave Radial Air Bearings which support it from the outside.

W-Profile

Our W-Profile Radial Air Bearing profile features a Concave or Convex radius cut across the width of the Air Bearing.

L-Profile

The L-Profile Radial Air Bearing profile features a Concave or Convex radius cut across the length of the Air Bearing, to meet the needs of your application and the bearing-to-shaft ratio of your specific configuration.

mm

Radial air bearings are non-contact bearings, ideal for frictionless rotational and/or axial motion applications. Due to their concave or convex shape, the radial air bearings form around the outer or inner diameter of the supporting shaft, ring or other artefacts. The air bearing uses a thin film of pressurized air to support the artefact. Pressurized air flows through porous media in the air bearing to create a thin air film that lifts the artefacts approximately 5 microns away from the bearing surface. This results in a non-contact situation where it can move or rotate freely to achieve frictionless motion.

Radial air bearings can be used in a number of applications, such as rings, drums, cylinders, shafts, discs and many more or when the radius you want to support is too big for an air bushing, for example. Industries where radial air bearings are commonly used are:

We can help you find the perfect radial air bearing for your specific application. Feel free to contact us straight away.

Radial air bearings are a natural choice over rolling element bearings for applications requiring a combination of high speed and repeatable motion. The main advantages to radial air bearings are:

In addition to the benefits of air bearings in general, such as:

Are you wondering if you can upgrade your traditional bearing for air bearings? Feel free to contact us straight away.

The load capacity depends on the size and air pressure of the bearing. Every variant has an ideal load stated in our radial air bearing portfolio. Measured with a fly height of 5 μm, our standard radial air bearings have a load range from 22 N to 10 kN. The bigger the bearing and/or the bigger the input pressure, the higher the load capacity.

Are you wondering if your application is suitable for radial air bearings? We can help you choose the right radial air bearing. Feel free to contact us straight away.

During a loss of air pressure or complete loss of air supply, the radial air bearing depressurizes itself and the rotating artefact slowly comes to a stop because air pressure is distributed across the whole bearing surface. Also, when this happens at extreme high speeds, the graphite material acts as a protective layer to prevent scratches or damage. Even when any small scratches occur on the air bearing surface, it will still be fully operational due to the millions of holes in the porous material.

Do you have more specific questions about radial air bearings? Feel free to contact us straight away.

Radial air bearings can be fixed using ball studs. Something to keep in mind is that it is crucial that the concave/convex surface of the bearing runs parallel to the deflecting shaft. When the bearings are mounted using ball studs, they are able to articulate and self-align to the deflecting shaft. Even a few microns of deviation in misalignment across an average-sized air bearing would significantly degrade the bearing's performance. Because of the need for constant alignment with your running surface, it is difficult, if not impractical, to bolt bearings in place in a rigid fashion.

We can help you find the best mounting possibilities for your specific application. Feel free to contact us straight away.

More questions? Read more Air Bearings FAQ's