Frictionless torque testing in Automotive

Case study - Magtrol has successfully implemented both radial bearings and air bushings into their torque test and calibration suite to improve product quality

When extreme precision is needed in your machine, tool, inspection or transport systems, air bearings are the natural choice.

Many of today’s manufacturers are faced with the increased demands of high-speed operations, coupled with extreme levels of precision. These unique requirements drive the need for machinery and tools which avoid friction to operate with high accuracy and reliability.

Air bearings provide an outstanding solution avoiding the traditional bearing-related problems of friction, wear and lubricants. One of the greatest benefits is that they provide new options for designers to push the envelope on precision, high speed, and high acceleration applications. Whether you’re an OEM or an Integrator, these porous media air bearings are not only a great technology but an outstanding product. Off-the-shelf or designed for your application, our years of experience with world beating precision design is here to help you change your paradigm.

The advantages of designing with air bearings:

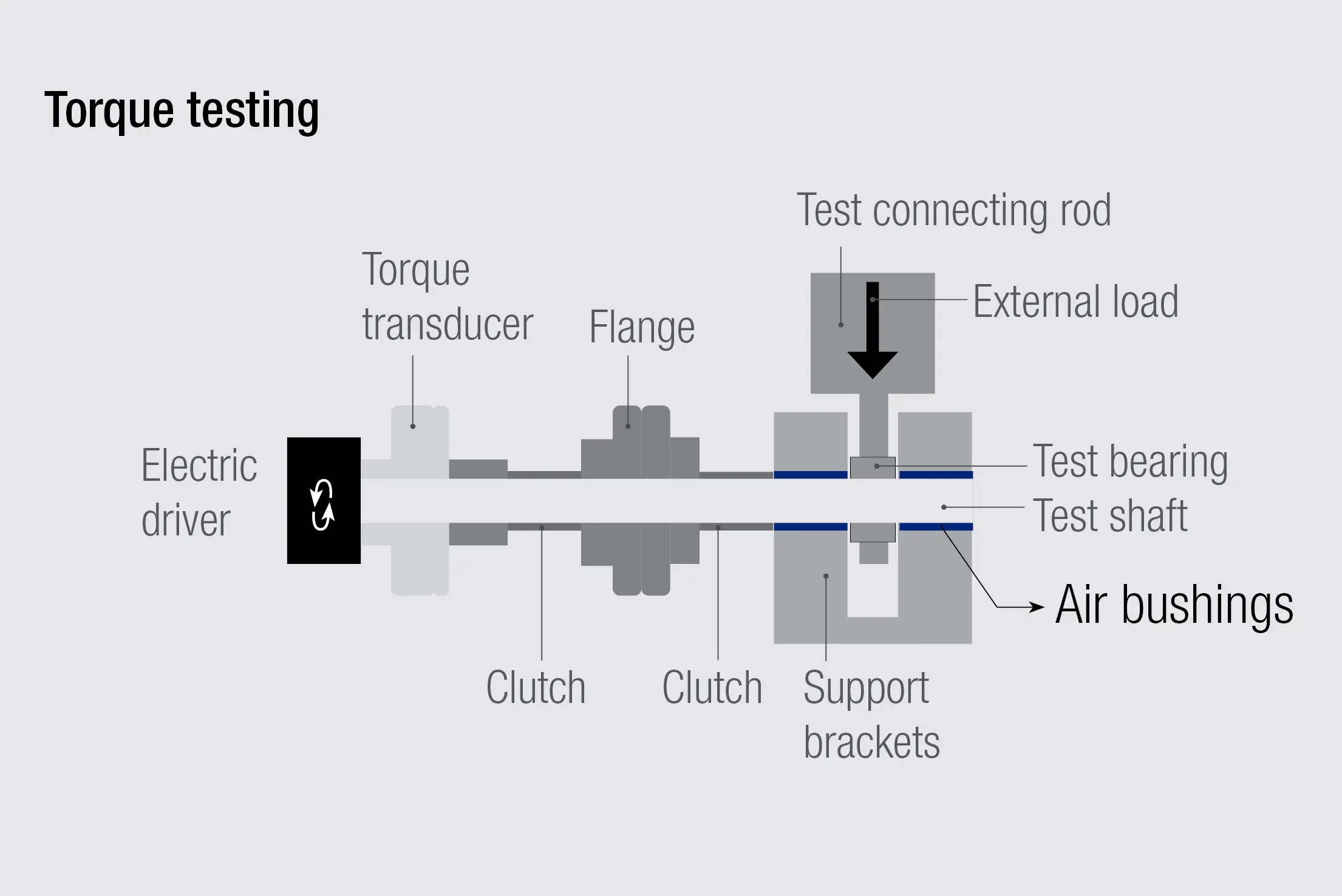

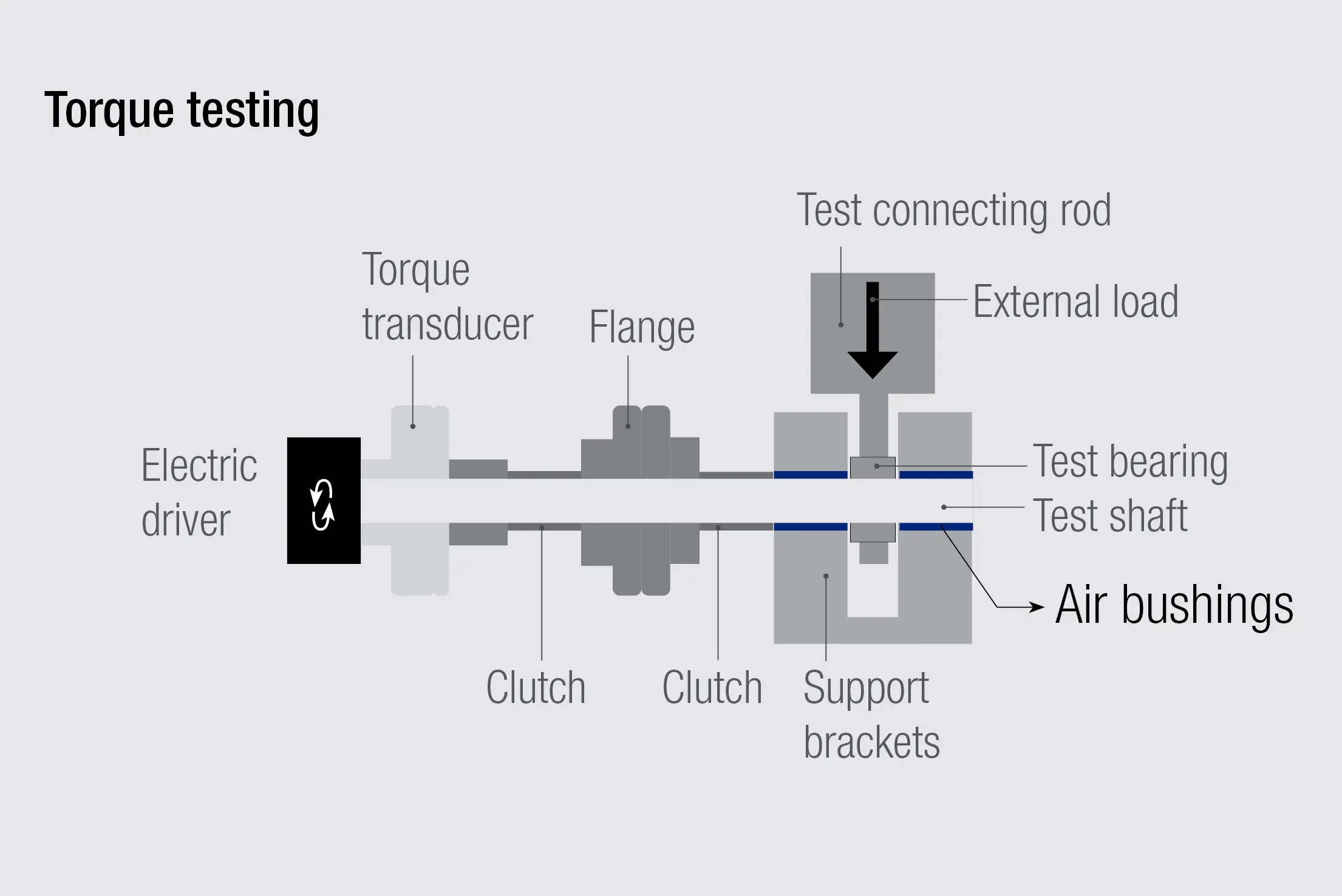

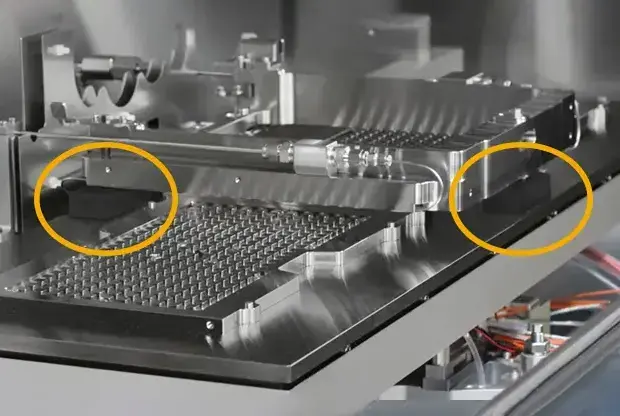

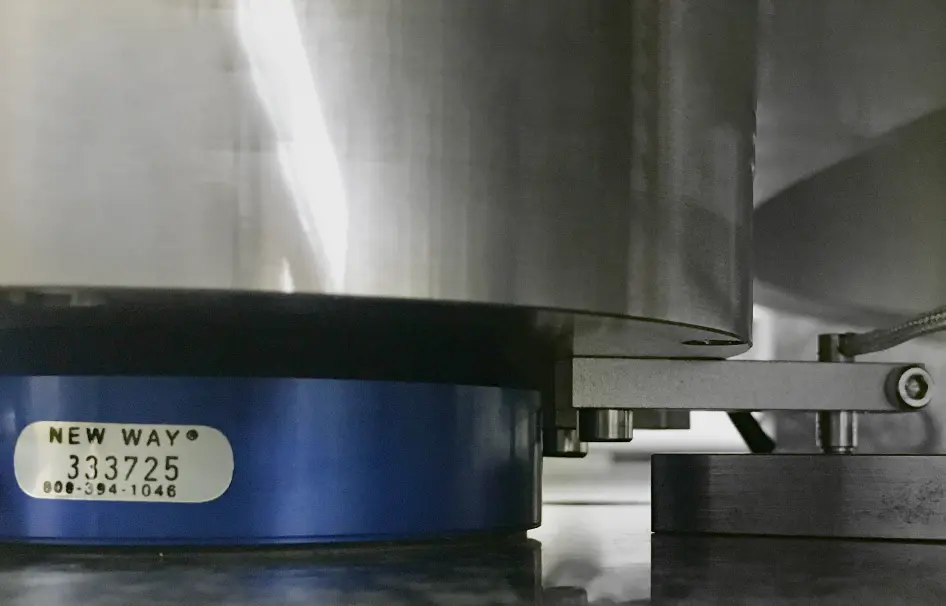

Case study - Magtrol has successfully implemented both radial bearings and air bushings into their torque test and calibration suite to improve product quality

Case study - IBS supported SparkNano in their high-temperature Spatial ALD application, with the integration of custom made full carbon air bearings, designed to withstand up to 250°C.

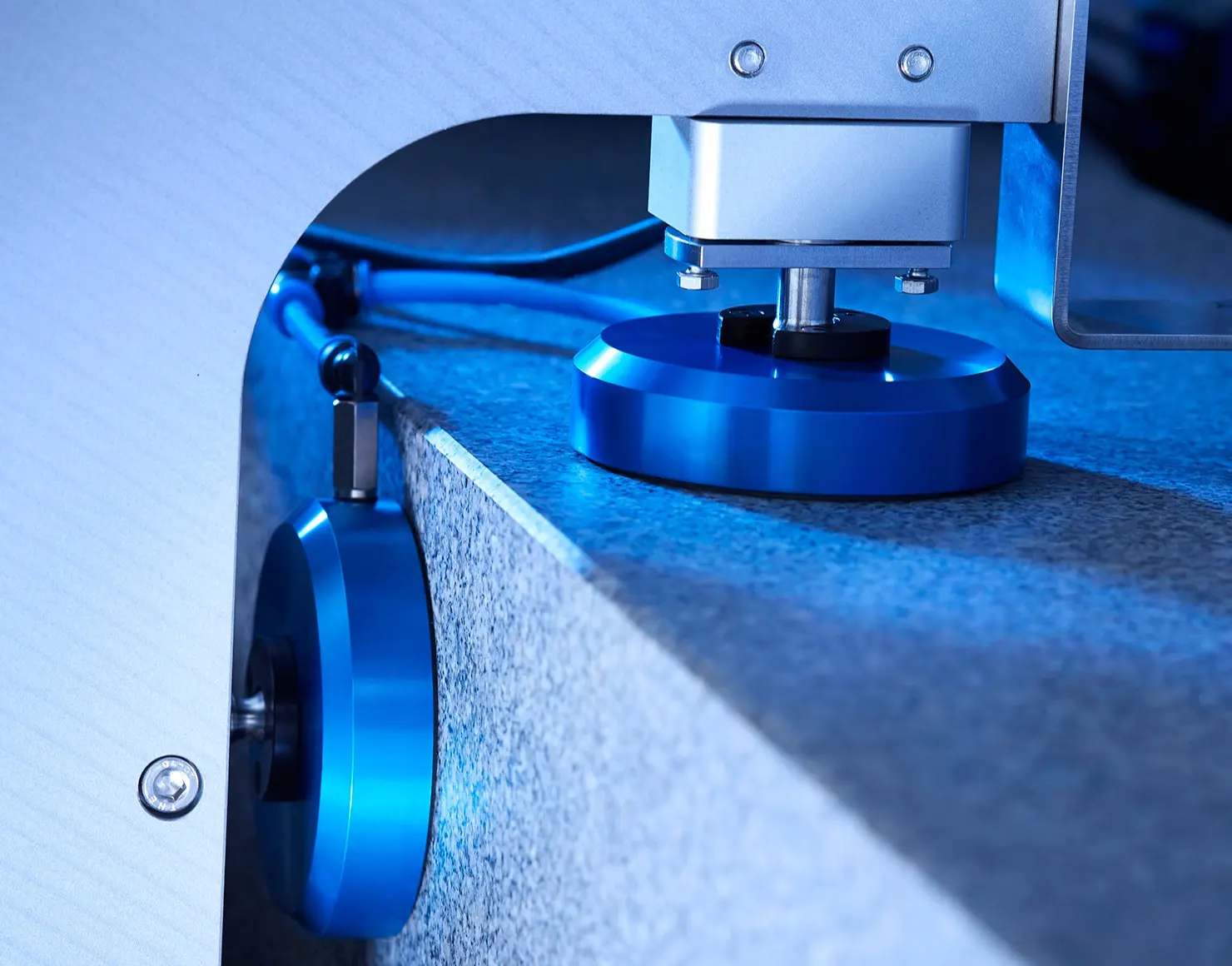

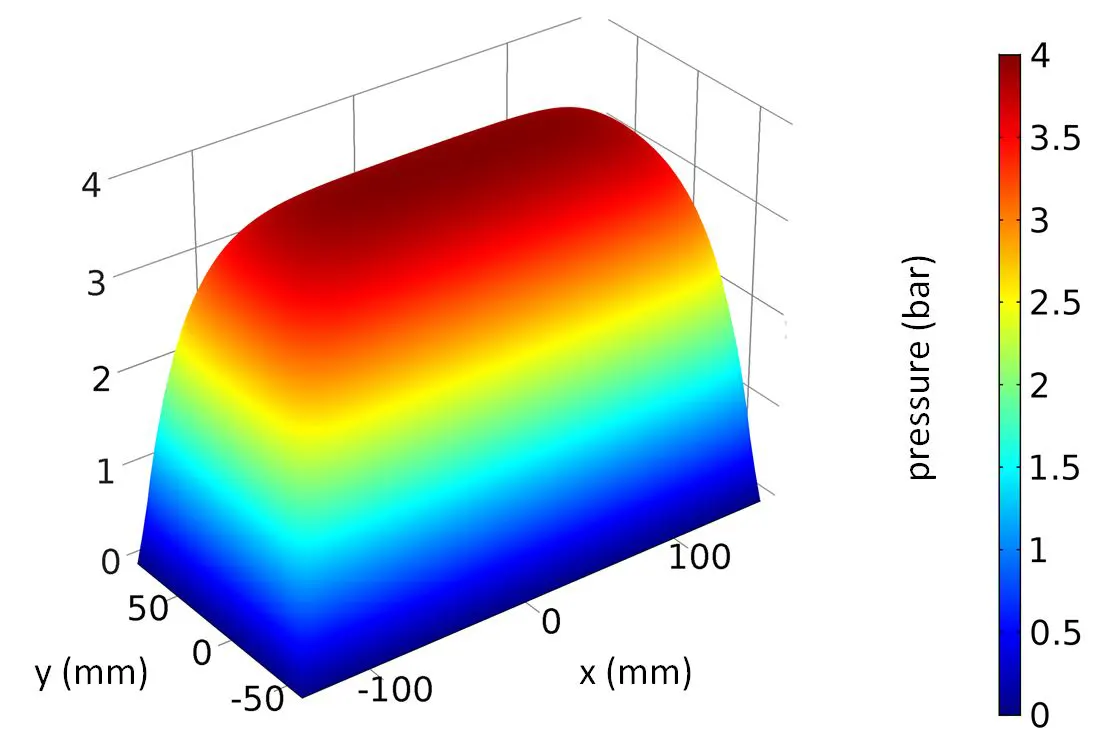

An Air Bearing was tested under a 570N payload and 5 bar operating air pressure. The results show that the Air Bearing is quiet, with a noise level of less than 2.5nm. The noise level is reduced when air is applied.

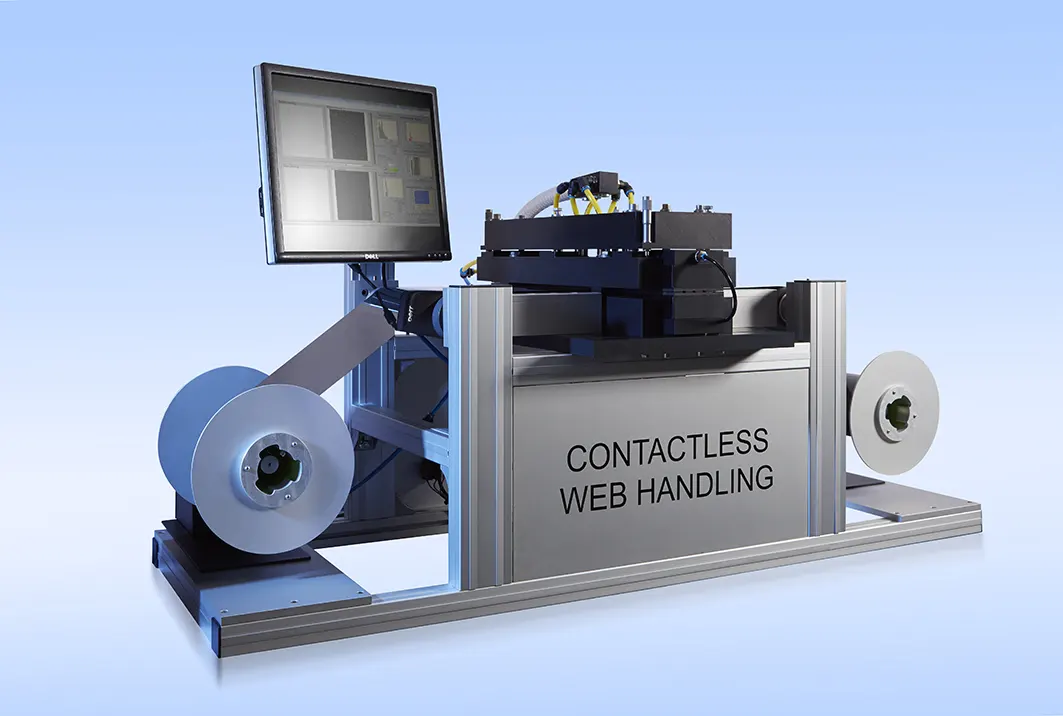

Exploiting air bearings in roll-to-roll. Non-contact, almost zero friction, and no static build-up benefits production processes.

In roll-to-roll processes for printed electronics, avoiding web contact is critical to reduce damage and contamination. Air bearings deliver contactless, precision control for printing, drying and inspection processes.

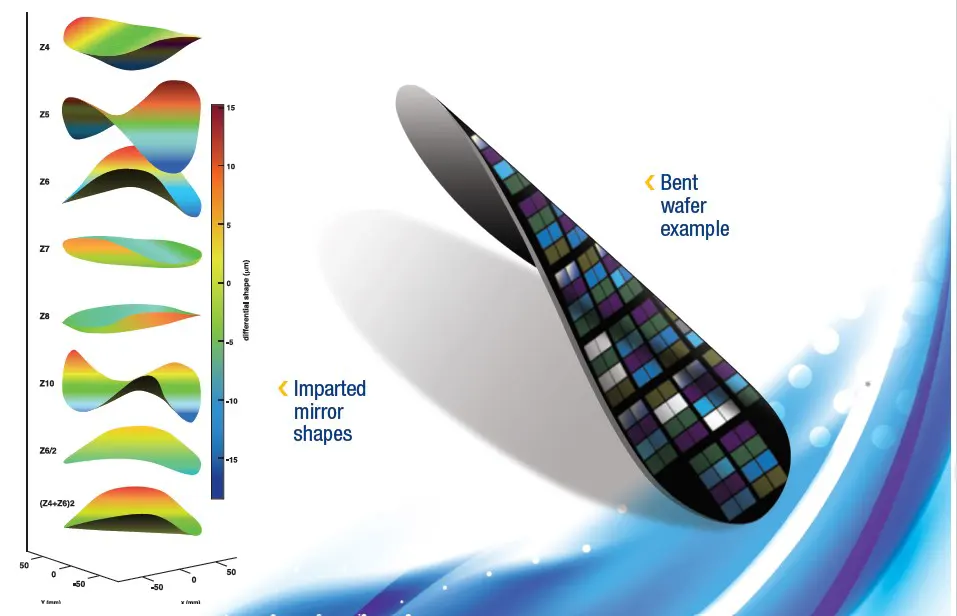

How can you shape substrates to your wishes without even touching them. Read how the magic is done.

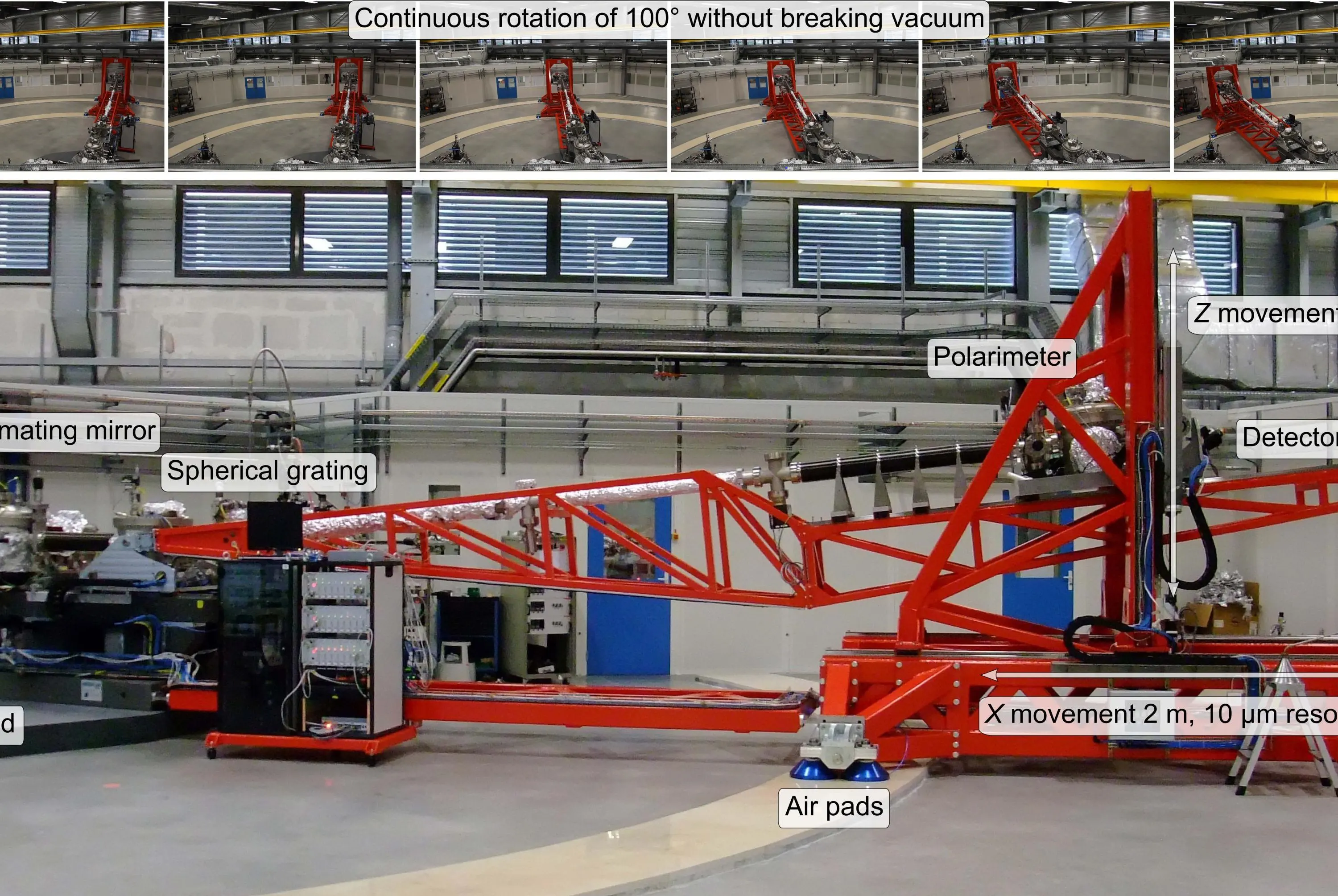

Air bearings can be exploited by mechanical engineers to extend their design capabilities for precision manufacturing systems. Read about some surprising new applications.