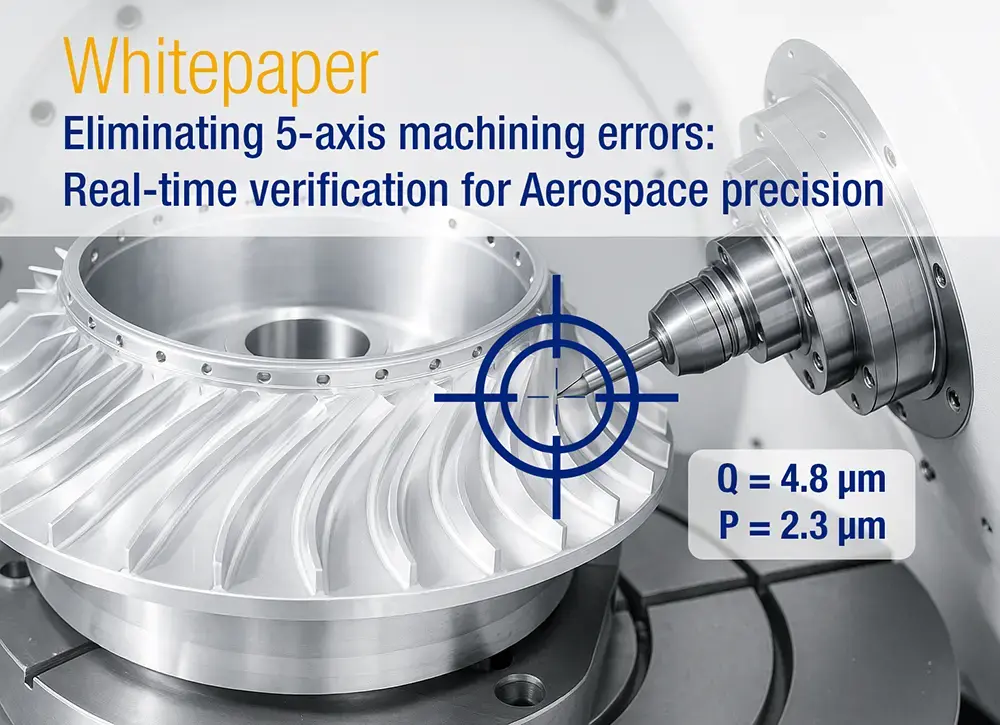

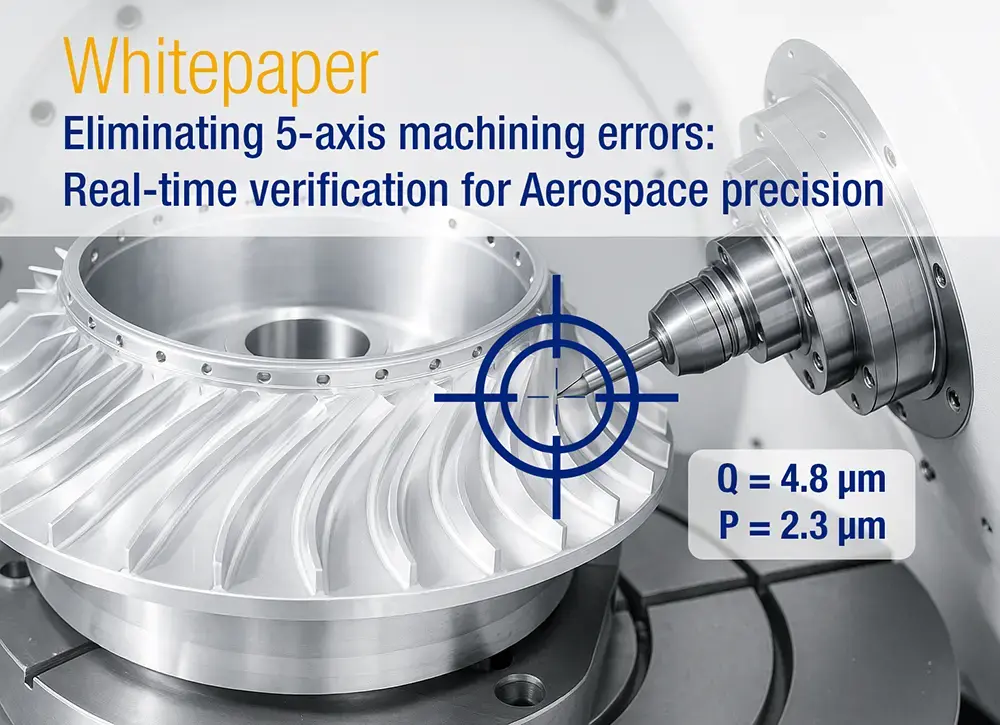

Real-time 5-axis machining verification for Aerospace precision

The Rotary Inspector performs ISO 10791-6-based dynamic measurements in <1 minute and delivers Q/P KPIs as a digital quality report, enabling rapid correction and audit-ready proof.

A range of products to provide peace of mind and control by guaranteeing your machine is within specification. When you require precise measurement, rapid results and tangible improvements.

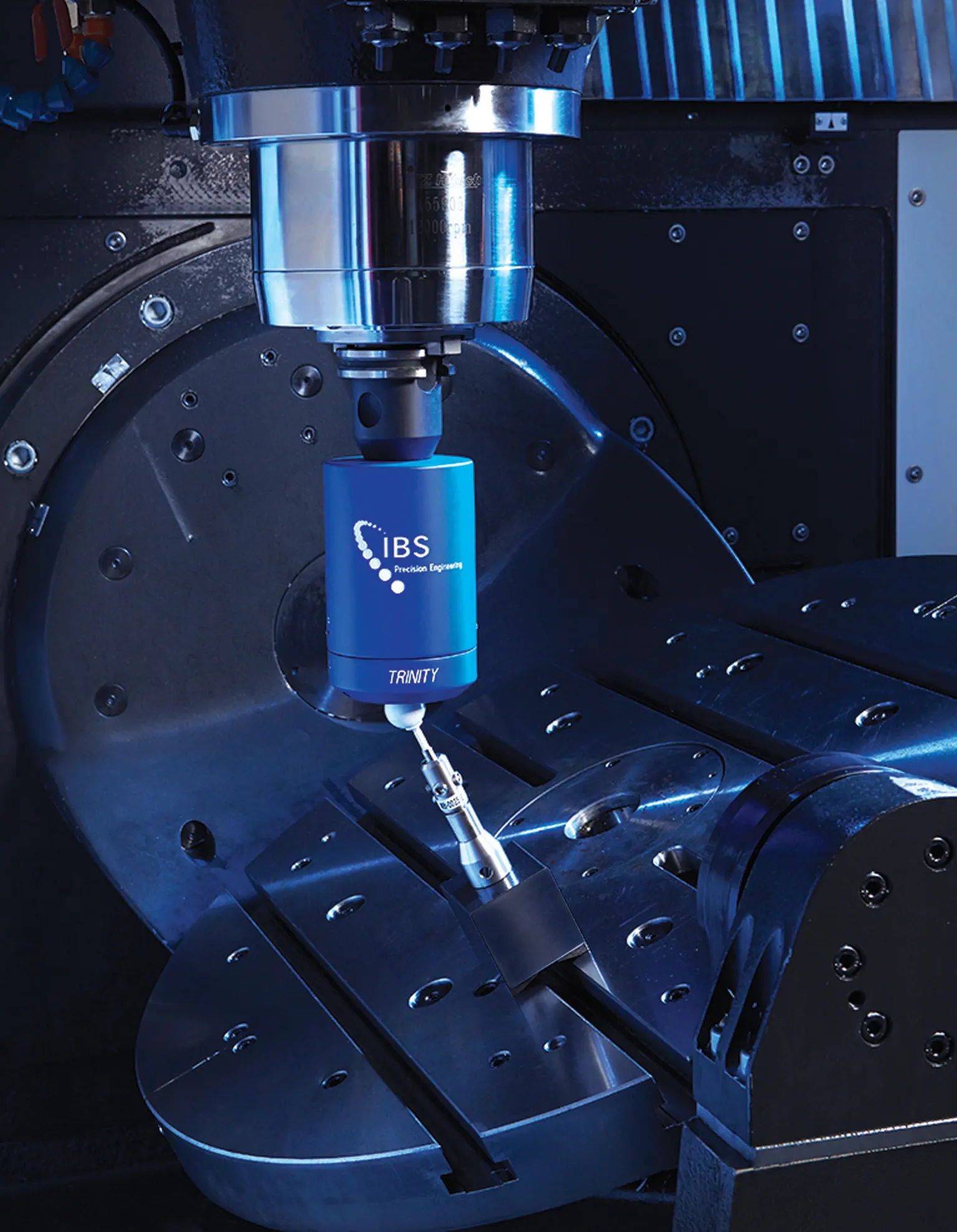

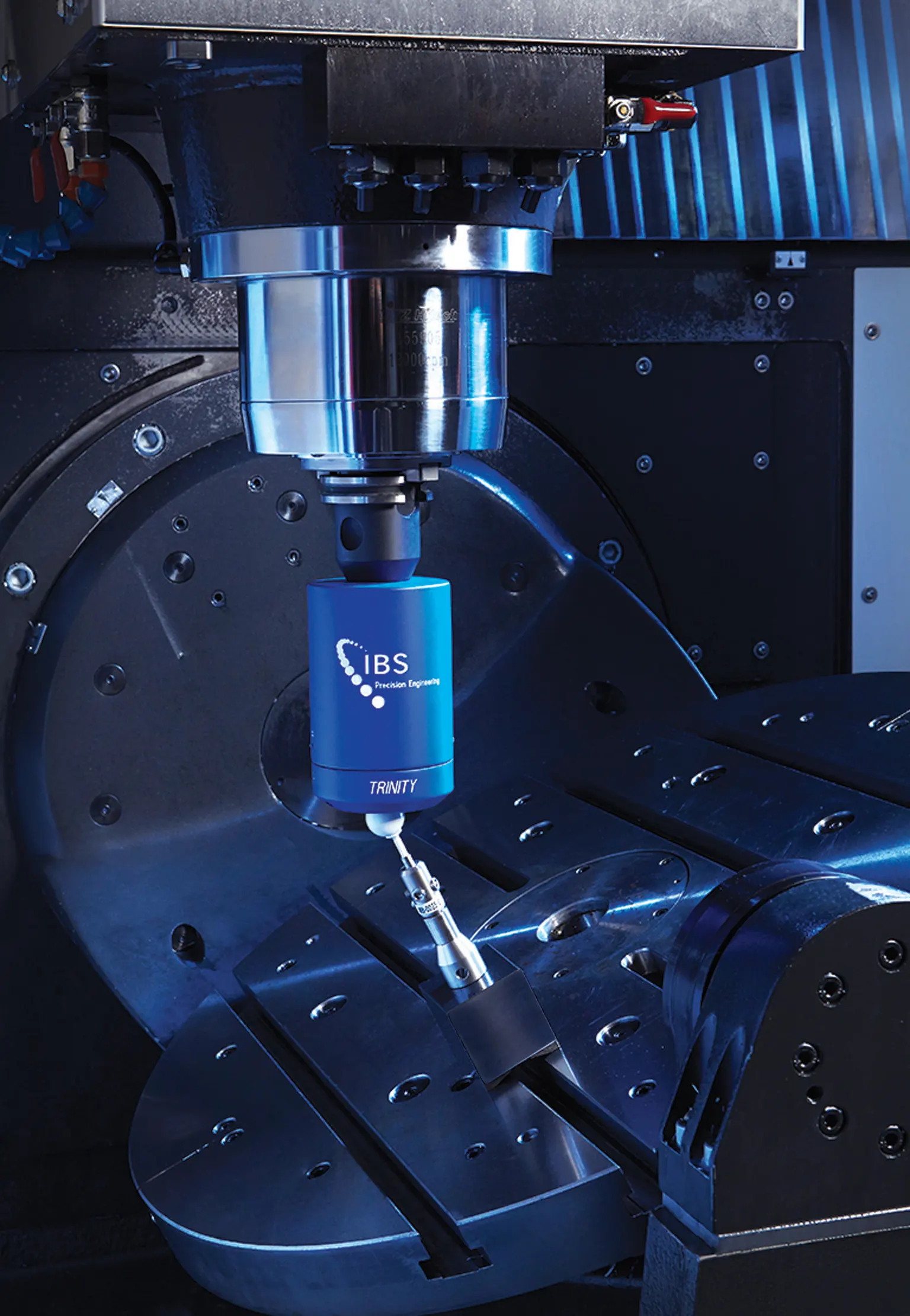

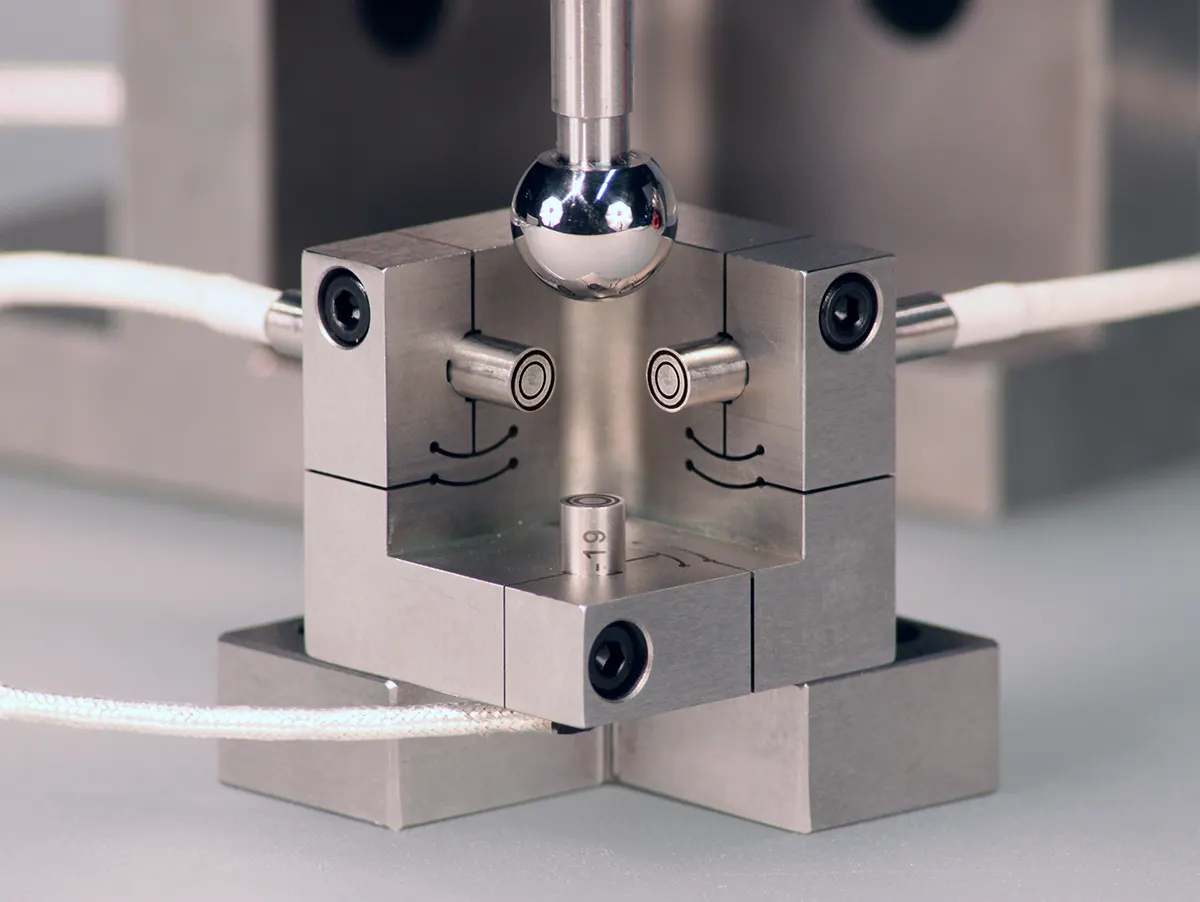

Machine-integrated, workshop robust Inspector Systems provide rapid and automatic qualification of cutting position, rotary table characteristics or spindle behavior.

For machine tool builders, maintenance providers and other advanced users Analyzer Systems offer in-depth measurement and diagnostics.

Simple go/no-go testing supports machine management and reduces out-of-tolerance products. On-line performance data makes tracking, reporting and maintenance planning easy.

Machine acceptance, qualification, compensation and alignment at your fingertips. ISO standards applied.

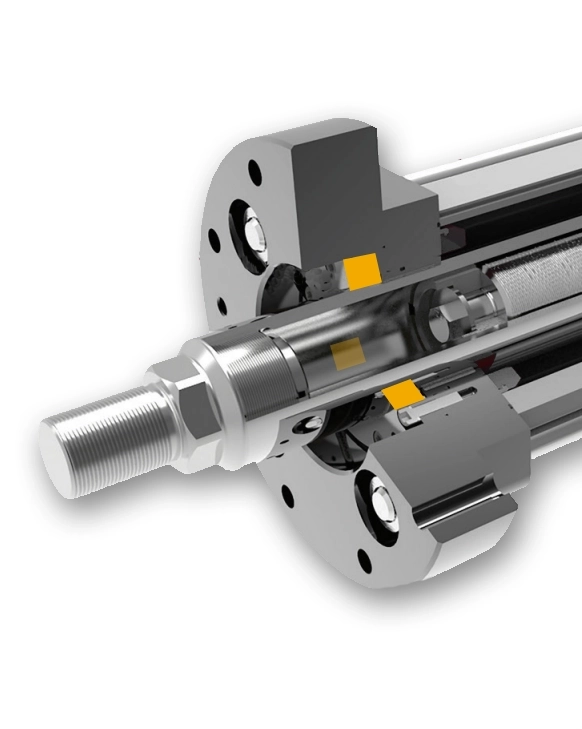

Rapid and automatic verification of your machine tool linear axis.

In-depth analysis and diagnostics of your machine tool linear axis

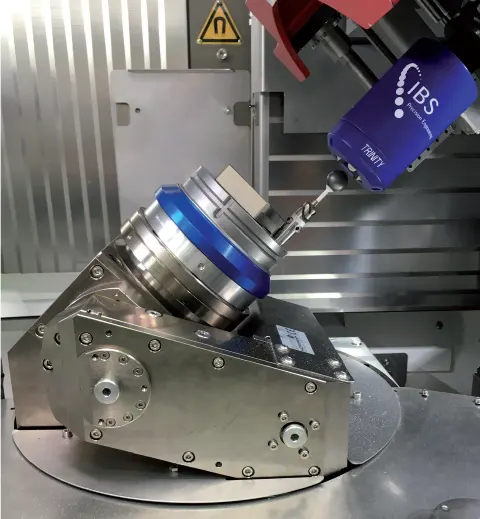

Rapid and automatic verification of the total 5-axis performance of your machine tool.

In-depth analysis and diagnostics of your machine tool 5-axis performance.

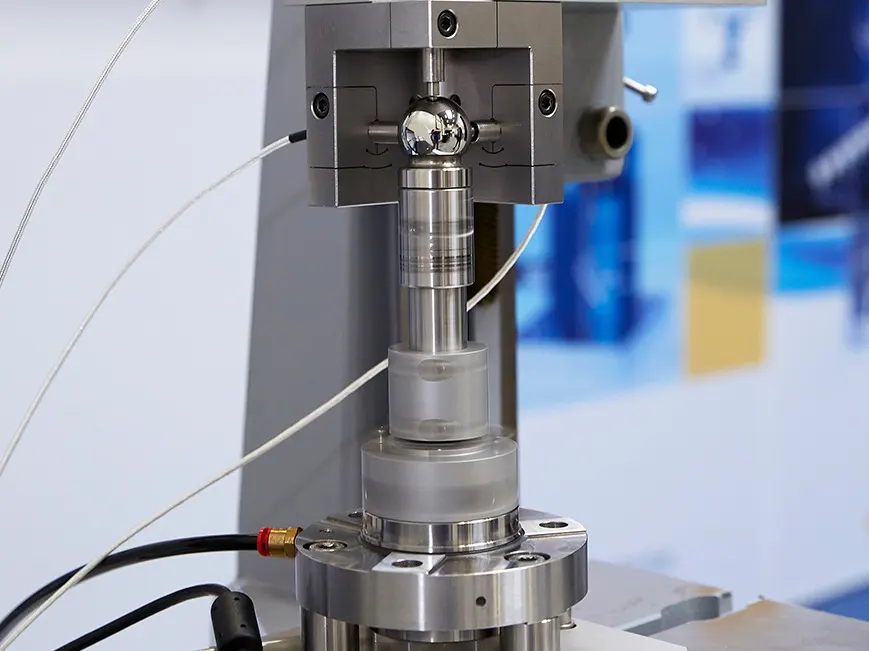

Real-time and automatic verification of your spindle accuracy and performance.

For in-depth, spindle accuracy and performance assessment.

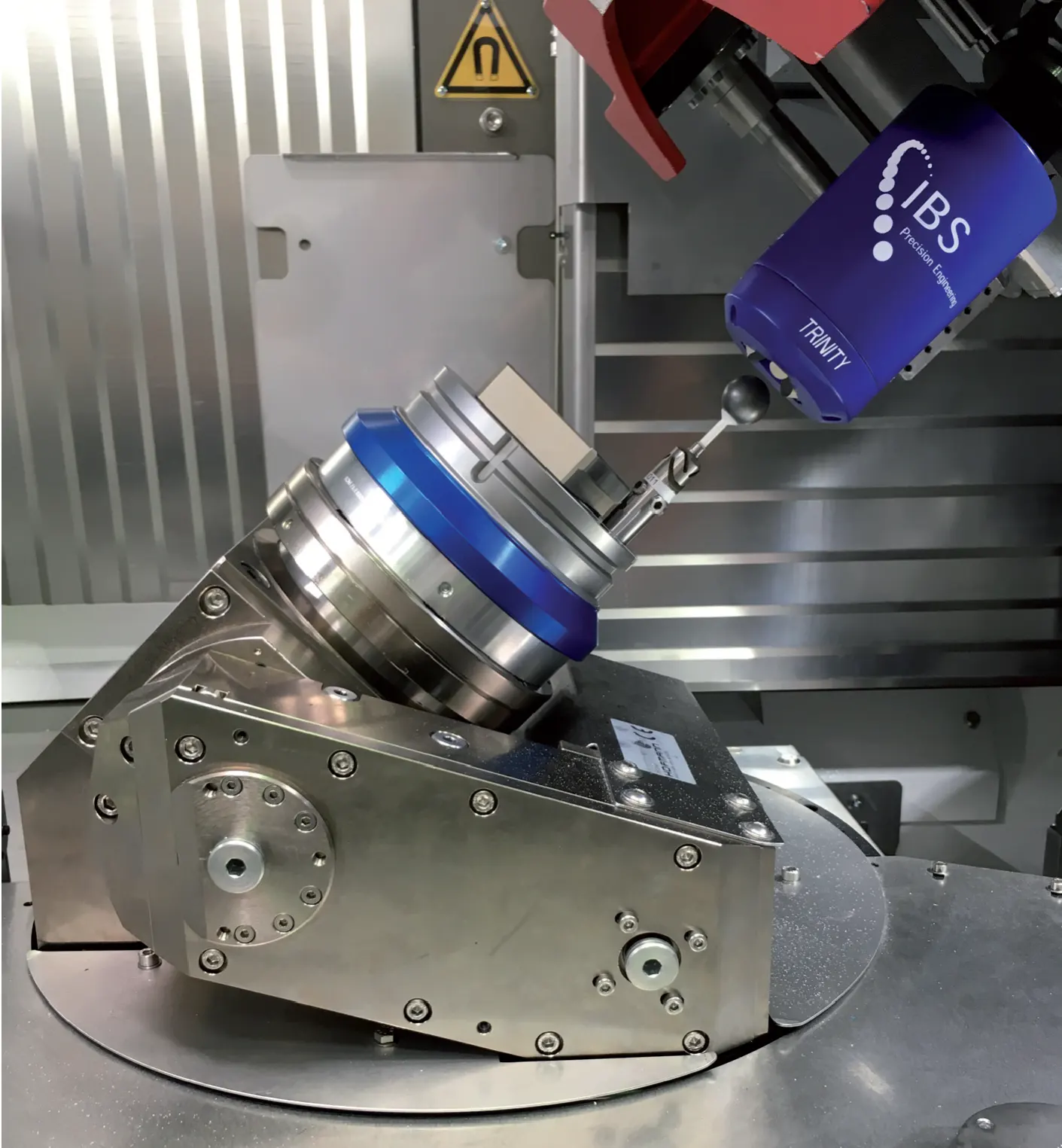

The Rotary Inspector performs ISO 10791-6-based dynamic measurements in <1 minute and delivers Q/P KPIs as a digital quality report, enabling rapid correction and audit-ready proof.

This whitepaper presents an analysis on the stability of the pivot line of rotary axes using a fast and accurate 3D measuring method to determine the dynamic 5-axis performance of the machine.

In the course of machine tool accuracy investigations many methods have been developed. This paper focuses on methods suitable for automation and hence industrial application.

Turbine manufacturing is a high-complexity, high-precision process requiring true 6-axis grinding. Read how Blohm Jung are addressing this challenge.

At IBS we support companies to measure and optimise their machines, in line with best practice. This article presents a fast and accurate method for the dynamic 3D measurement of thermal stability