- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

For ultra precision in distance, position and motion measurement.

When your product or application needs accurate and reliable motion or position control engineering, capacitive measurement can provide an outstanding solution. With proven performance advantages such as outstanding accuracy and high speed, you can achieve the system performance you need.

As a world-leader in precision systems, we offer a range of sensors to meet your wishes: resolution, speed, ease of integration or all three.

We have experts in-house with unique experience on the integration of sensor systems plus short lead times and the ability to customise your sensors to your requirements, to bring your high-tech products to market in a way that achieves lasting ROI. For scientific instrument makers, our know-how brings the benefit of a partner who guarantees measurement confidence and traceability.

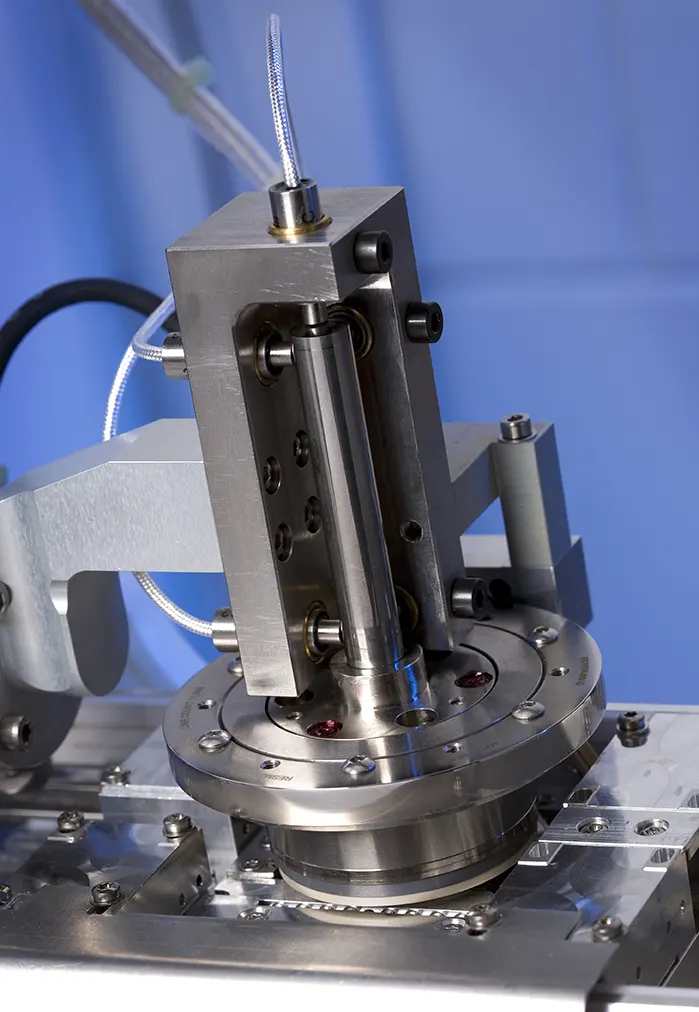

Each of our capacitive position or displacement measuring systems comes with a range of possible probes. System performance is determined by the selected probe. In this way the optimum solution for your requirements can be specified.

A guard ring surrounds the sensing element and focuses the electric field toward the target. Electronic components are connected to the sensing element and guard ring. All of these assemblies are surrounded by an insulating layer and encased in a stainless steel housing.

Capacitive sensors use a high frequency electric field for sensing, usually between between 500 kHz and 1 MHz. The field is focused by the guard ring resulting in a spot size about 30% larger than the sensing element diameter. A typical ratio of sensing range to the sensing element diameter is 1:8. This means that for every unit of range, the sensing element diameter must be eight times larger. For example, a sensing range of 500µm requires a sensing element diameter of 4000µm (4mm). This ratio is for typical calibrations. High resolution and extended range calibrations will alter this ratio.

The amount of current flow in the electric field is determined in part by the capacitance between the sensing element and the target surface. Because the target and sensing element sizes are constant, the capacitance is determined by the distance between the probe and the target, assuming the material in the gap does not change. Changes in the distance between the probe and the target change the capacitance which in turn changes the current flow in the sensing element. The sensor electronics produce a calibrated output voltage which is proportional to the magnitude of this current flow, resulting in an indication of the target position.