- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

Fast and high precision interferometer solutions for areal surface measurements of micro and nanoscale structures; including stepped and freeform surfaces.

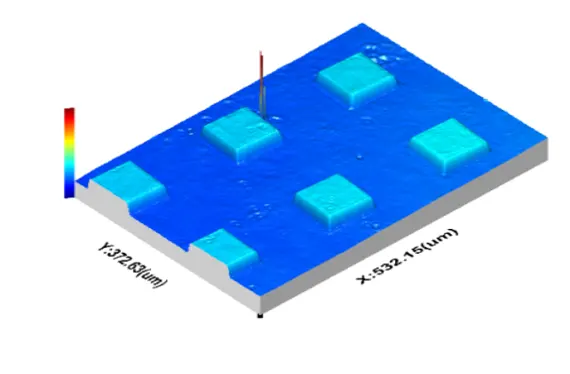

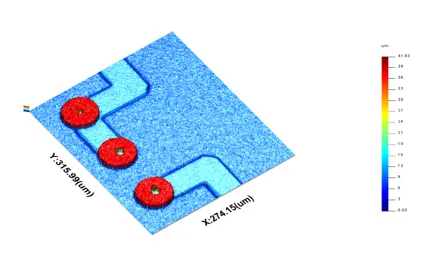

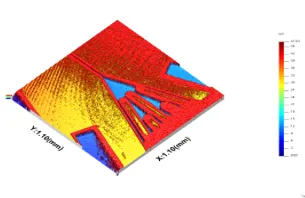

When you need to achieve quality control of surface features at the micro and nanoscale in production, interferometry offers advantages such as high speed, precision and no contact. If the features include steps and freeforms, interferometry can also give you the data you need.

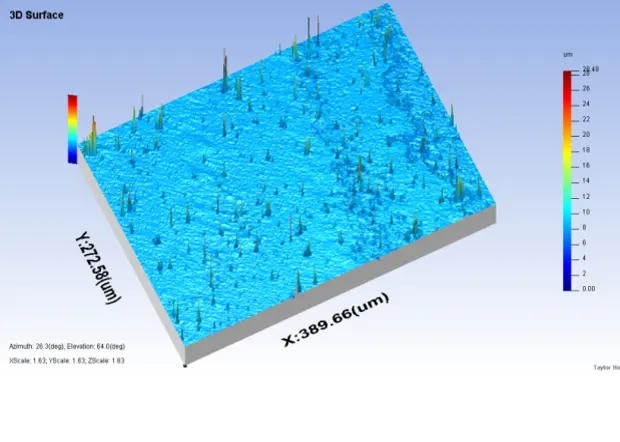

Structured surfaces, designed for a particular function, or unintended features, as in surface damage or unwanted particulates, play a critical role in more and more precision products. Surface data is required just in time to support effective production. We have interferometer solutions that deliver the measurement data you need just when you need it.

These systems offer the measurement capability you need plus the capability to integrate directly into your production environment.

Fast and high precision interferometer solutions for areal surface measurements of micro and nanoscale structures; including stepped and freeform surfaces.

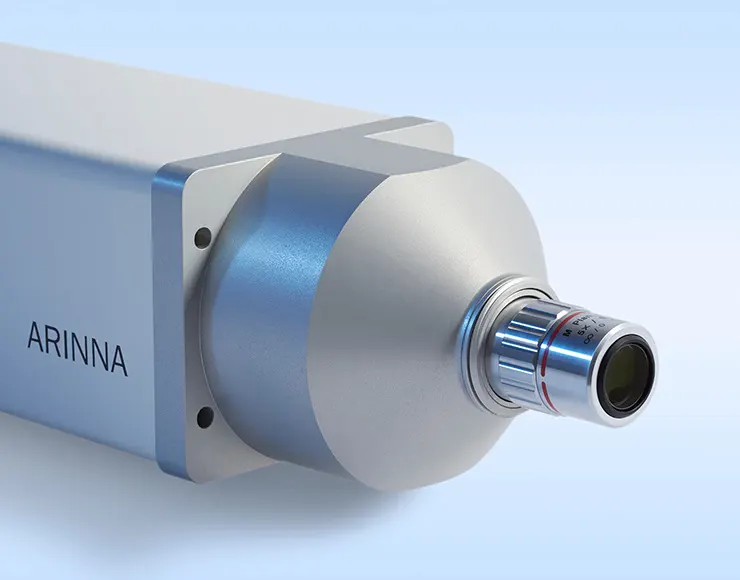

ARINNA is a high speed interferometer that combines the advantages of nanoscale surface measurement with ruggedness and a small footprint that allows it to measure in-line, just where you need it. While interferometers bring the advantage of speed, accuracy and non-destructive measurement, stepped structures and noisy environments have usually been their limitation. Not so with ARINNA.

The wavelength scanning technique employed by ARINNA avoids the need for mechanical scanning in the measurement head, as employed by some interferometric systems. This overcomes associated limitations to both the measurement speed and system integration (such as the ability for 360 degrees orientation of the head). For in-line use, a patented vibration compensation technique has been integrated into the design of ARINNA. This technique avoids the need for large and/or complex isolation systems; at times a limiting factor in the application of high precision optical measurement systems in the field.

ARINNA is able to measure discrete step heights and surface quality with a vertical resolution <2nm. A mega pixel camera captures a surface scan in under 1 sec. It can be used for in-line defect detection and characterisation, optical surface and structure measurement, 3D surface topology measurement, MEMS/NEMS inspection and more.