- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

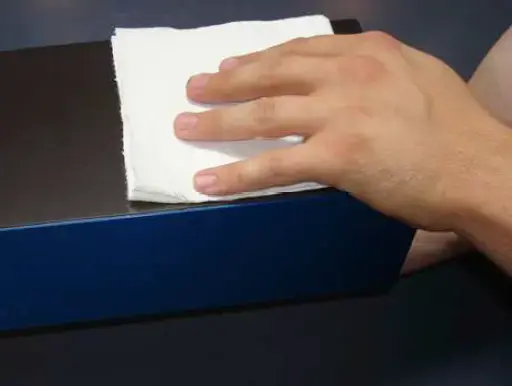

Learn the essential air supply specifications necessary for optimal air bearing performance and detailed cleaning instructions to maintain their precision and longevity. Ensure your air bearings operate smoothly and efficiently with key insights and practical steps for proper maintenance.

DO NOT OPERATE THE AIR BEARINGS UNLESS AIR PRESSURE IS APPLIED!

The compressed air which you supply our air bearings with must be properly cleaned and dried. Air bearing performance and useful lifetime greatly depends on the quality of your air supply. An efficient system will ensure minimal pressure loss as well as the removal of contaminants such as water, oil, dirt, rust and other foreign particles. It is strongly advised to use a filtered air supply, ideally of ISO-class 3, but at the very least ISO-class 4. See ISO-table below for specifications.

Depending on the application, porous media air bearings may need air pressures ranging from 2 to 25 bar. However, for the majority of applications, 4.1 bar is typically sufficient.

IBS Precision Engineering recommends a surface finish of 0.4 Ra (μm) / 0.44 RMS (μm) or better. Although rougher surfaces may be adequate, we ask that you discuss your specific application with us before employing air bearings in such a situation. For porous media air bearings, the surface finish must be considered as being part of the gap, so surface finishing becomes more crucial as you design for smaller gaps.

![]() Our air bearings have been verified to satisfy the requirements of ISO 14644-1 Class 3 cleanliness, with airborne particulate concentrate limits of less than 1,000 x 0.1μm particles / m³.

Our air bearings have been verified to satisfy the requirements of ISO 14644-1 Class 3 cleanliness, with airborne particulate concentrate limits of less than 1,000 x 0.1μm particles / m³.

Additionally, the porous media itself acts as a sub-micron filter, so the air flowing out of the bearing is inherently clean, making it plausible for their usage in cleanrooms as clean as Class 1.