- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

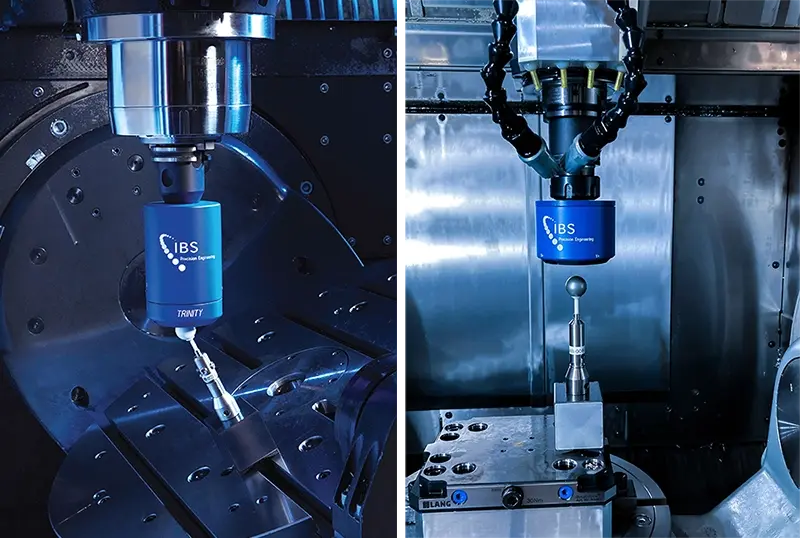

Our Trinity and Trinityᵐ wireless probe systems are high-precision non-contact measuring systems, designed for fully automated machine performance verification. Both systems feature tool-changeable probes that operate automatically within your process. Compare the two to discover which best fits your specific requirements.

Maintaining geometric accuracy in machine tools is critical to ensuring consistent part quality, reducing scrap rates and minimizing downtime. In multi-axis machining environments, even small deviations in linear or rotary movements can have significant impact on the production performance.

Maintaining geometric accuracy in machine tools is critical to ensuring consistent part quality, reducing scrap rates and minimizing downtime. In multi-axis machining environments, even small deviations in linear or rotary movements can have significant impact on the production performance.

Our machine tool inspection and analyzer series offer a range of measurement systems to provide peace of mind by guaranteeing your machine is within specification. The Position and Rotary Inspector and Analyzer series employ IBS Precision Engineering’s patented wireless Trinity & Trinitym probe systems for linear and rotary axis measurement. Unlike other systems the Trinity probe systems’ unique design enables the execution of non-contact X, Y and Z measurements simultaneously with exceptional measurement speed and accuracy. The probe systems are designed for quick and accurate qualification of 3-, 4-, 5- and even 6-axis machines.

The probe is mounted in the spindle and a calibrated masterball or linear array is positioned on the machine table. As the spindle moves along a predefined path, the probe, representing the Tool Centre Point (TCP), measures its position relative to the masterball. This setup allows the system to capture positional errors in real time across multiple axes.

With this data, the operator can immediately visualize deviations in the cutting path. Errors such as pivot line misalignment, squareness issues and linearity deviations become apparent, allowing corrective actions to be taken before they affect production.

In addition, both Trinity probe systems reveal problems like dynamic instability, incorrect controller settings or bearing degradation, issues that are often difficult to diagnose with conventional tools. The measurement uncertainty is less than 1 μm, providing the level of precision needed for demanding applications.

Trinity

3.50 mm

Trinityᵐ

2.00 mm

Trinity

0.25 μm

Trinityᵐ

0.2 μm

Trinity

2 kHz

Trinityᵐ

2 kHz

Trinity

U₁D < 1,0 μm (within 1 mm range)

Trinityᵐ

U₁D < 1,0 μm (full range)

Trinity

17 hours

Trinityᵐ

13 hours

Trinity

42 hours

Trinityᵐ

100 days

Trinity

2.4 GHz frequency, 802.11b/g/n standard, WPA2-security

Trinityᵐ

2.4 GHz frequency, Bluetooth 5.0, dedicated bonding, 6-digit PIN security

Trinity

ø = 16 mm

Trinityᵐ

ø = 10 mm

Trinity

Length: 135 mm; Diameter: 80 mm

Trinityᵐ

Length: 60 mm; Diameter: 80 mm

Trinity

770 grams

Trinityᵐ

325 grams

Trinity

22 mm

Trinityᵐ

22 mm

Trinity

75 mm

Trinityᵐ

75 mm

Measuring range

3.50 mm

2.00 mm

Resolution

0.25 μm

0.2 μm

Sampling rate

2 kHz

2 kHz

Measuring uncertainty

U₁D < 1,0 μm (within 1 mm range)

U₁D < 1,0 μm (full range)

Measuring time continuous

17 hours

13 hours

Lifetime sleep mode

42 hours

100 days

Wireless details PSK

2.4 GHz frequency, 802.11b/g/n standard, WPA2-security

2.4 GHz frequency, Bluetooth 5.0, dedicated bonding, 6-digit PIN security

Probe mounting shaft

ø = 16 mm

ø = 10 mm

Dimensions

Length: 135 mm; Diameter: 80 mm

Length: 60 mm; Diameter: 80 mm

Weight

770 grams

325 grams

Diameter (normal)

22 mm

22 mm

Length

75 mm

75 mm

Trinity and Trinityᵐ provide robust solutions for technical machine qualification tasks. Their wireless design, measurement precision and portability enable efficient integration into manufacturing environments where accuracy and uptime are critical. These tools serve as reliable components in predictive maintenance strategies, supporting both cost efficiency and production consistency.

For larger machines or those requiring an extended measurement range, the Trinity probe variant may be the better choice. Trinity offers a range of 3.5 mm and Wi-Fi connectivity, making it more suitable for large-scale applications.

Due to its reduced footprint, the Trinityᵐ probe is suitable for smaller machines where space is limited. It offers improved measurement accuracy (export controlled) and an extended battery life achieved through power-saving technology. For additional operational safety, an optional emergency stop (E-stop) feature is available.

Contact us, if you have questions about these probe systems, or if you would like to receive more detailed specifications or integration guidance.