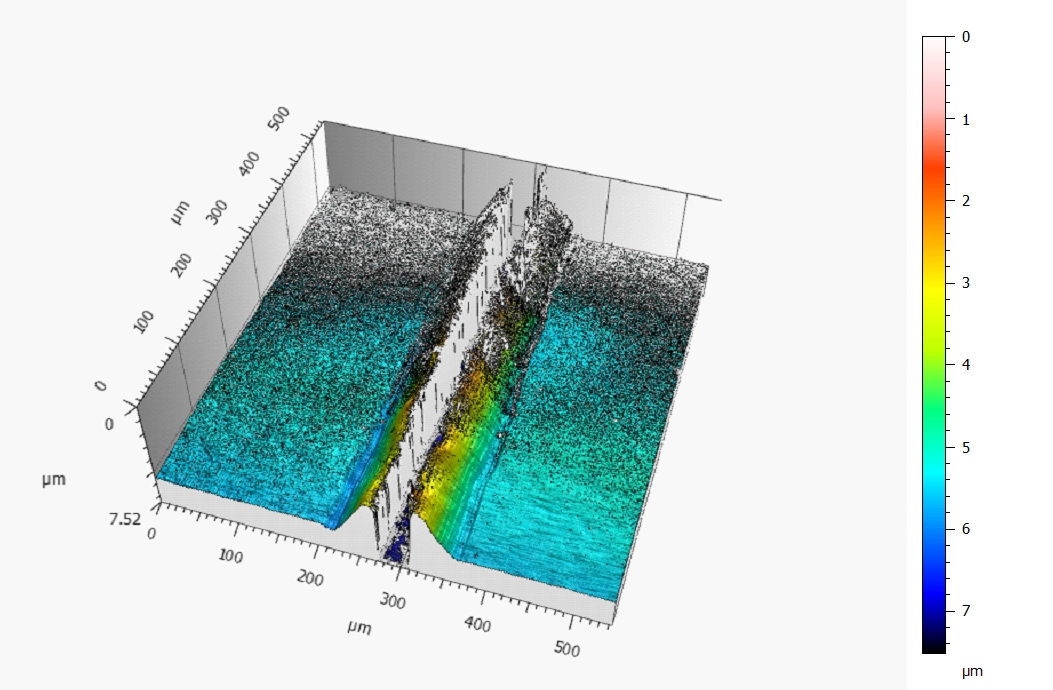

Dances with foils - In-line interferometry in R2R production

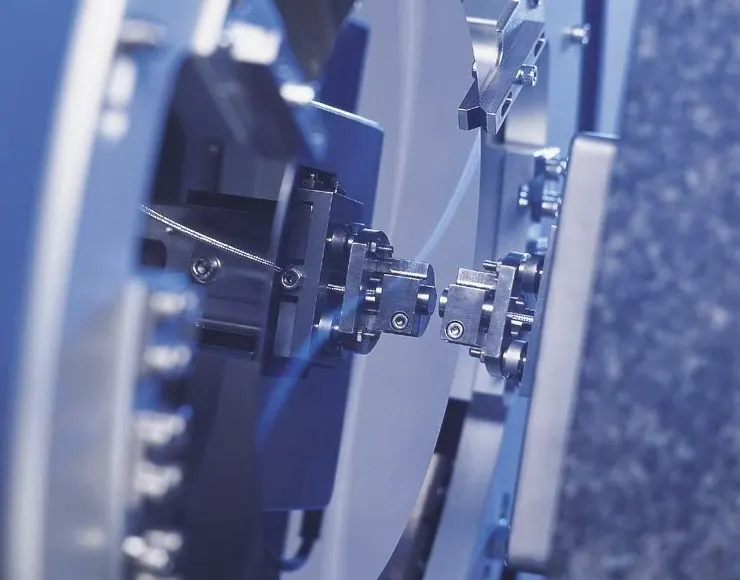

In the production of flexible electronics, in-line 3D metrology of nanometer-scale features revolutionise the production process making time-consuming off-line measurements for process control unnecessary.