The name IBS Precision Engineering is representative of what the Eindhoven company excels in: developing measuring equipment for machines that need to be verified in any way. Van der Nolle explains; “we mainly focus on precision measurements”. “With our measuring instruments, we help companies find solutions to optimize their machines. Or to measure their products to the utmost precision. You can imagine that these kinds of solutions are needed in many places. There are therefore several providers in the market. However, out of all these parties we set the bar on the highest possible position, especially when it comes to accuracy and reliability.”

Precision measurements without interruption

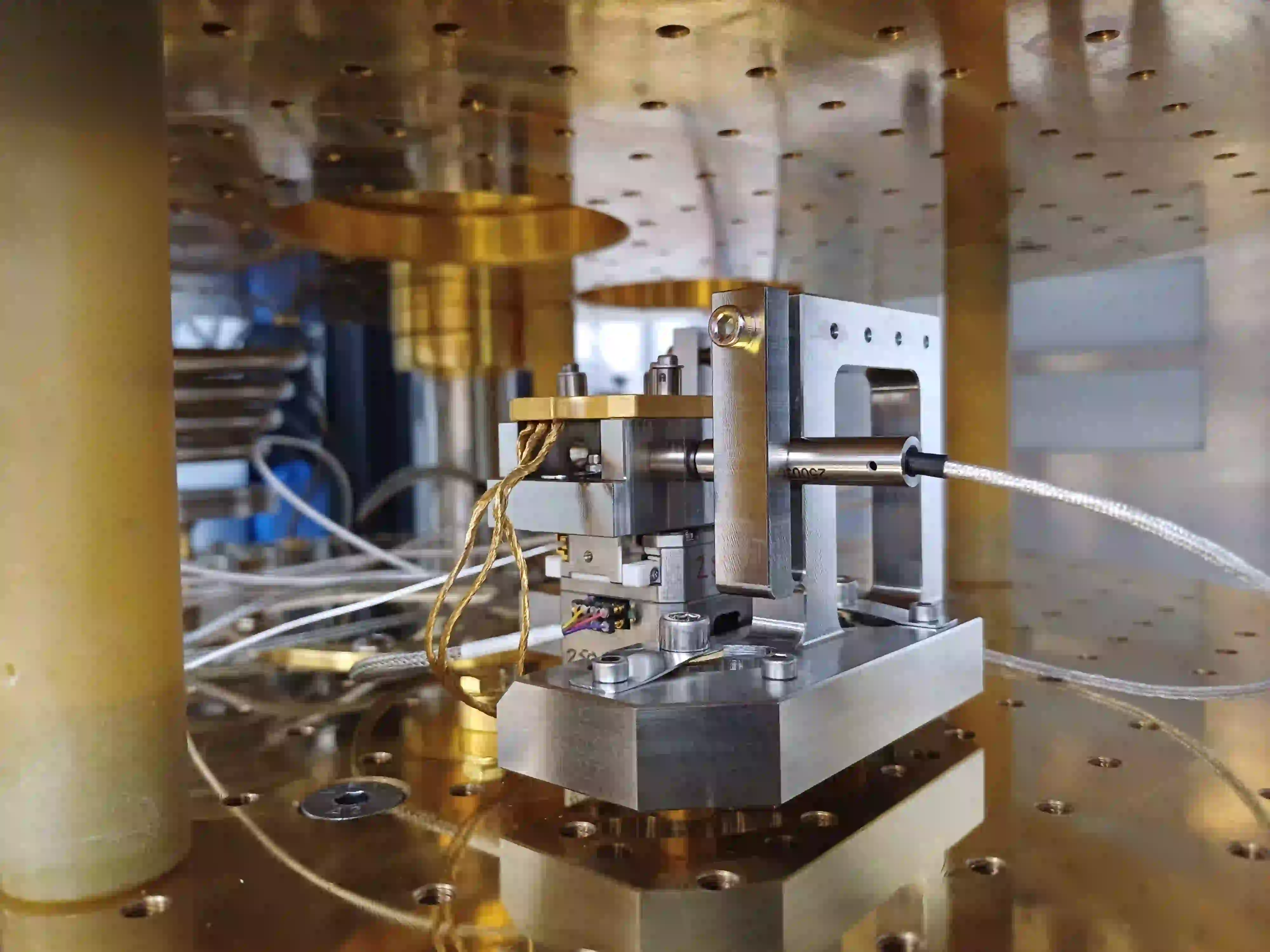

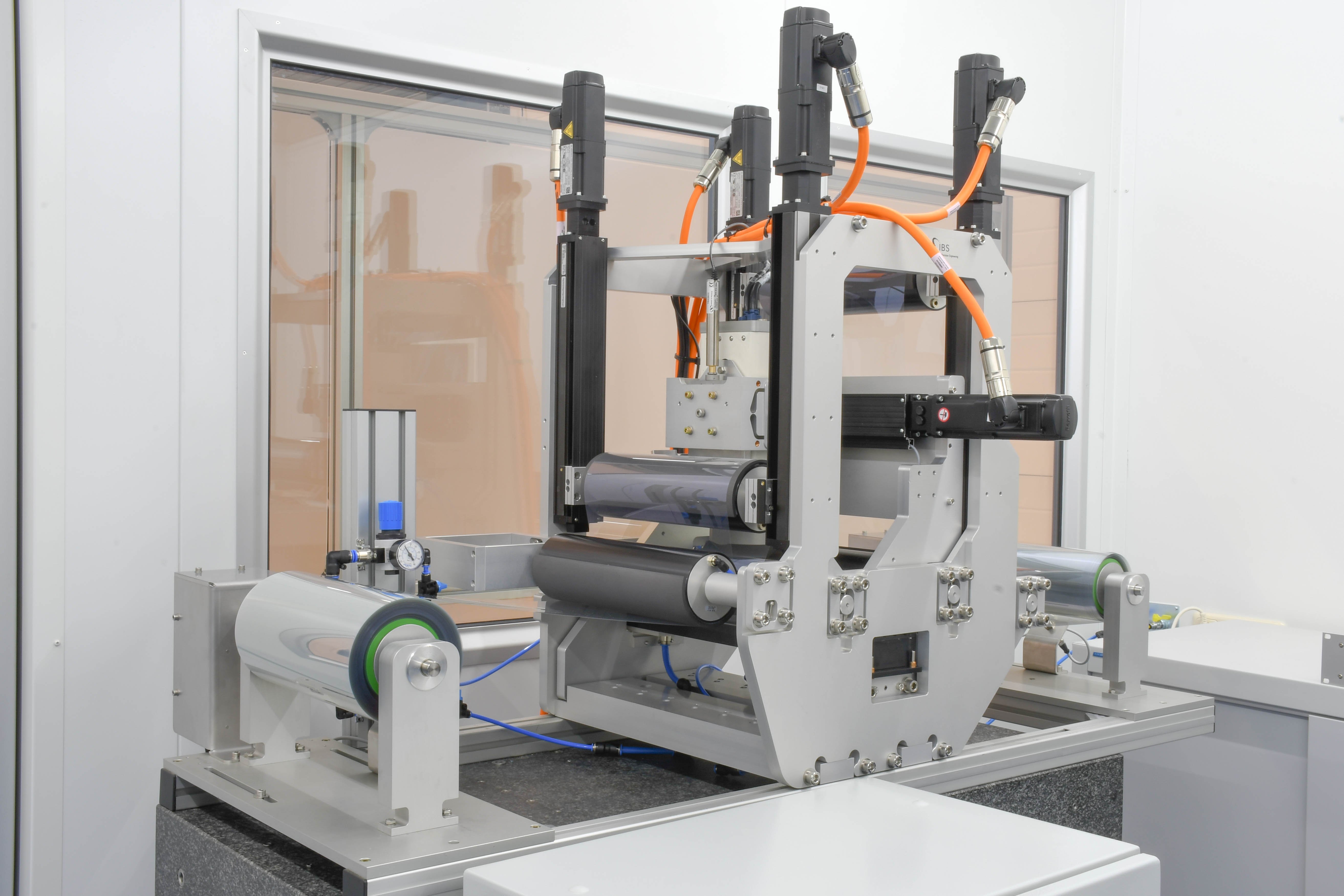

That bar was therefore also high at the development of a linear precision module for highly accurate surface measurements of foil with flexible electronics or solar cells. This module was intended to control a proprietary system that measures "grooves" in the width and depth of the film. Thanks to smart mechanical components, this innovative system makes it possible to perform precision measurements without interrupting the production of the film.

“Our time savings? From three weeks to two seconds!”

Van der Nolle: “By using this new technique, we can perform in-line measurements. Thereby, all system components play a crucial role in this, because it involves measurements of moving material in a fraction of a second. By measuring in-line and therefore "in the moment", we save a lot of time. Previously, the customer had to cut a piece of foil and send it to a laboratory. It sometimes took up to three weeks before the result of the measurement came in. With this system we achieve the same result, but within two seconds. Moreover, we now also measure the depth of the grooves in the foil. In short: a huge gain in time, but also in quality.”

Interesting issue

During the search for a supplier of linear precision modules, IBS came to Bosch Rexroth. They immediately found the issue of IBS particularly interesting, according to Werner Knapen. “During our first conversation it soon became clear to me that this was a very innovative machine. But more importantly, I instantly knew that we could help IBS with its development. That is because they did not think the drive of the module may be possible using standard units, while our IndraDrive servo controllers and servo motors are perfect for these types of applications.”

Coincidentally, IBS had already decided that the machine should run on Labview. That choice was technically and practically completely in line with the possibilities of IndraDrive, according to Knapen. “Because our IndraDrive servo controllers automatically support Labview, we were able to guarantee IBS lightning-fast implementation. With a direct connection and without function blocks. Within a month, the entire project including the controls was finished. To be honest, we were also amazed of the smoothness of that operation.”

“Within a month, the entire project including the controls was finished”

Smooth collaboration

Both Van der Nolle and Knapen look back on a smooth and successful collaboration. At IBS, they also perceive the outcome as an important result within their international Smartline project. They are responsible within that project for the development of a tool that makes it possible to measure laser writers on OPV and OLED printed electronics in-line.

Van der Nolle: “During this project, we gained an enormous amount of new knowledge and insights about that subject. Furthermore, the measuring machine does exactly what it has to do, so we are also very satisfied with that. At the same time, of course, we continue to set the bar high. For example, it would be great if we could find out how we can get even more precision out of the engines. It is very likely that we will involve Werner and his colleagues again.”

About IBS Precision Engineering

IBS Precision Engineering has been helping customers meet their measurement, positioning and motion systems requirements for ultra-high precision for more than 25 years. Based on an expert foundation in metrology, the company understands the true meaning of precision.

About Bosch Rexroth

Bosch Rexroth is a global player in hydraulic technology, electric drive and control technology and linear motion and assembly technology. The company has offices in more than 80 countries and achieved a turnover of approximately 6.2 billion euros in 2018 with approximately 32,300 employees.

Driven by Servo, controlled by Labview

The developed measuring system is integrated in a production line of flexible electronics and solar cells. The installation takes a snapshot of the film, so that a measuring head developed by IBS can accurately measure the quality of the layer on the film with nanometer precision. The measuring system is driven by a Labview application and powered by five IndraDrive servo controllers, five MS2N servo motors with single cable technology and five PSK linear precision modules.