- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

Spindle performance can be critical to the quality, productivity and efficiency of a machine. When you need absolute confidence in your spindle performance, the Spindle Error Analyzer is the industry leading solution for in-depth spindle accuracy and performance assessment.

High performance non-contact measurement with sub-nm resolution.

Tests compliant to latest ISO230 standards.

Dynamic spindle performance, thermal drift, spindle tilt, reversal errors and shift versus rpm built in.

Suitable for a wide range of ultra precision and high speed spindles and rotary.

At IBS we have been specialists in spindle measurement and optimisation for decades. We apply this not only for our customers machines but also for the ultra precision machines we build. Together with our partner in non-contact sensor technology, Lion Precision, we offer the Spindle Error Analyzer (SEA). This outstanding solution for spindle quality control gives best-in-class, clear and uncompromising results.

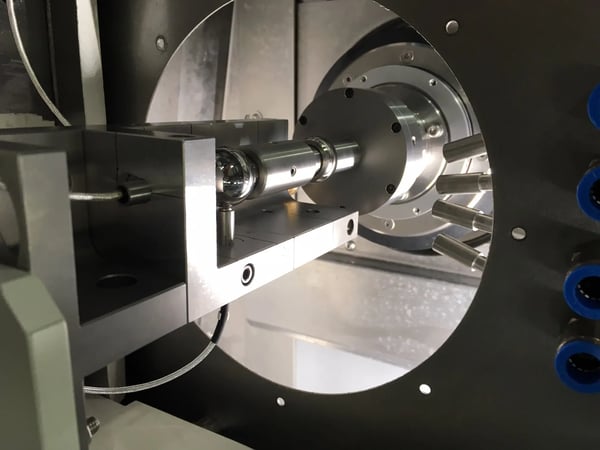

The system works by installing a precision target in the tool holder. Spindle motion is measured with non-contact capacitive probes mounted in a precision fixture. State-of-the-art algorithms analyse the results which are presented in easy to read charts and graphs