- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

We develop ultra precision, innovative solutions for our customer's precision challenges with passion and deep expertise. Our customers build on our decades of experience in their industries and rely on IBS to provide them with a step change in accuracy combined with confidence and trust in their production processes.

An innovation leader in the semiconductor industry, ASML’s lithography solutions have been making giant leaps on this tiny scale since 1984. In their technology, hardware meets software to provide a holistic approach to mass producing patterns on silicon. Their vision is to enable ground-breaking technology to solve some of humanity’s toughest challenges. Headquartered in Europe’s top tech hub, the Brainport Eindhoven region in the Netherlands, their operations are spread across Europe, Asia and the US. With a global team of more than 24,900 people from 118 different nationalities and counting.

ASML and IBS precision Engineering first came together in the early 2000s. Over the years this collaboration brought about many innovative ultra-precision modules and systems to help ASML achieve their increasingly challenging precision requirements. And to this day our semicon development road map is aligned with ASML, leading to joined R&D projects to advance the latest technologies in this industry. To study thermal behaviour of machines, for example, we have established the ATC consortium. As demanded by ASML from all suppliers, IBS needs to adhere to the highest standards, given the importance of accuracy and trust in this industry. Therefore, we are proud to be considered the go-to supplier for metrology expertise. Our in-house capabilities (read about our wafer shaping) and facilities (cleanroom ISO Class 5) help us to serve the semicon equipment industry with ground-breaking, state-of-the-art metrology systems.

Applied Materials is the leader in materials engineering solutions used to produce virtually every new chip and advanced display in the world. Their expertise in modifying materials at atomic levels and on an industrial scale enables customers to transform possibilities into reality. Applied Materials has transformed from a small start-up into one of the most admired companies in the world. They put the “silicon” in Silicon Valley, playing a key role in the evolution of the electronics industry. Headquartered in California’s Silicon Valley, the global team consist of 24,000 employees, who are active in more than 110 locations in 19 countries.

Applied Material has been a regular customer since the late nineties. The products we supply perform dedicated distance measurement in ultra-high vacuum, for Applied Materials wafer inspection machines. Our robust supply chain system, uninterrupted deliveries and our metrology expertise in general make IBS the go-to supplier for ultra-precision measurement solutions. IBS has aligned its development road map with Applied Materials, realizing digital systems with optimized materials for their latest metrology systems. All systems are calibrated and traceable to international standards.

Rolls-Royce pioneers cutting-edge technologies that deliver clean, safe and competitive solutions to meet the planet’s vital power needs. As the world’s population grows, and urban populations increase, a new approach to building and powering cities and developing more sustainable transportation is urgently needed. Moving to a low carbon global economy, their engines will become part of broader, hybrid-electrical systems with lower emissions and environmental impacts. Rolls-Royce are tightly focused into three core operating businesses: Civil Aerospace (aero engines), Power Systems, Defence (aero engines).

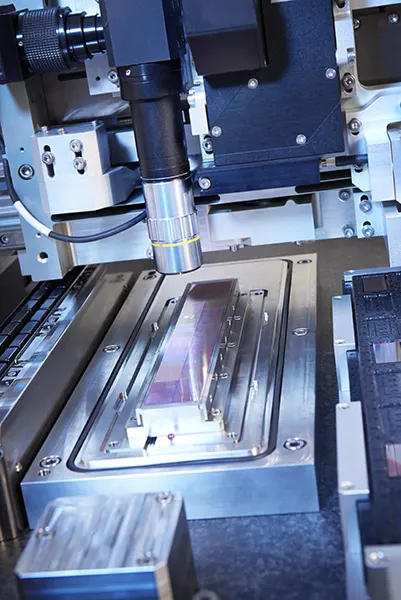

IBS is Rolls Royce’s partner in machine tool measurement and inspection since 2007. It started with spindle metrology on their high precision grinding machines. Soon after that we supplied inspection and analyzing software to improve 5-axis machine performance for Rolls-Royce’s high-pressure turbine blades. Our metrology systems are the standard for producing such blades in multiple locations across the globe. A recent development includes carbon fibre turbine blades for jet engines, where our measuring systems ensure the quality of complex 6-axis production machines.

Mercedes-Benz AG is responsible for the global business of Mercedes-Benz Cars and Mercedes-Benz Vans with over 173,000 employees worldwide. The company focuses on the development, production and sales of passenger cars, vans and services. Furthermore, the company aspires to be leading in the fields of connectivity, automated driving and alternative drives with its forward-looking innovations. Mercedes-Benz AG is expanding its worldwide production network with over 40 production sites on four continents, while aligning itself to meet the requirements of electric mobility.

For companies in the automotive market, like Mercedes-Benz, we supply technology to help make a step change in test and measurement performance. We supply non-contact air bearing technology for frictionless testing and rolling roads, testing the aerodynamic behaviour of cars and of components like tires. We provide engineering support for a seamless integration of air bearings in the testing process, to support the energy transition into electrical vehicles (EV). Our sensor technology is used for optimizing the efficiency of combustion engines and the latest brake disk technology. We align our development road map for optical technology, like ARINNA, which can be applied measuring structures needed for battery production.

At CERN, physicists and engineers probe the fundamental structure of the particles that make up everything around us. They use the world's largest and most complex scientific instruments to study the basic constituents of matter – fundamental particles. Subatomic particles are made to collide together at close to the speed of light. The process gives clues about how the particles interact, and provides insights into the fundamental laws of nature. The instruments used at CERN are purpose-built particle accelerators and detectors. Accelerators boost beams of particles to high energies before the beams are made to collide with each other or with stationary targets. Detectors observe and record the results of these collisions. Founded in 1954, the CERN laboratory in Geneva has now 23 member states.

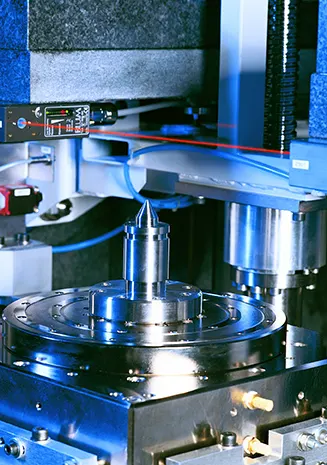

Our metrology expertise has been supplied to Cern since 2004 and this relationship has fruitfully expanded into the largest development contract given to a Dutch company; the development and realisation of ALICIA, a sensor module assembly machine, part of the ALICE detector upgrade. ALICE (A Large Ion Collider Experiment) is a detector dedicated to heavy-ion physics at the Large Hadron Collider (LHC). It is designed to study the physics of strongly interacting matter at extreme energy densities, where a phase of matter called quark-gluon plasma forms.

ALICIA was developed to measure and assemble the 15,000 sensor chips which make up the new detector. Working closely with CERN teams across the globe, the machine accommodated changing requirements as the sensor chip technology developed; from chip size to positioning accuracy and test protocols. The first machine, ALICIA 1, passed the site acceptance test at CERN and seven more machines have since been delivered by IBS to sites around the globe.

Canon is global leader in consumer and professional imaging. One of Canon’s goals is to be the #1 in printing. Canon Production Printing creates innovative and exceptional technologies, products and services for their main markets in printing and workflow management. The focus is on accelerating digital imaging technologies and developing high-tech printing products. Founded in 1877 in Venlo, the Netherlands, the company has a long history of technical innovation and development. A key asset is inkjet, a game-changing and widely applicable imaging technology. It is their ambition to build on their expertise in jetting for high-volume, high-speed printing.

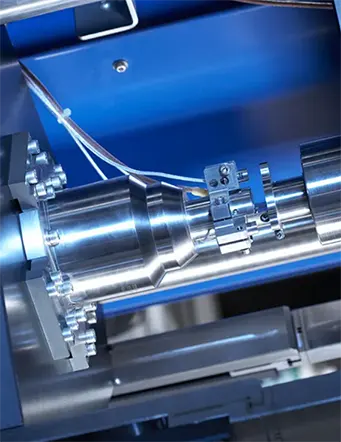

Back in 1993, the first contract IBS signed was with the company Océ, now known as Canon Production Printing. IBS created software which improved the accuracy of cylinders manufactured for large printing machines. Next steps were improving the accuracy of the process and imaging drums by developing new innovative metrology tools, which have been in use in Venlo (NL) for more than 20 years. The relationship developed in other demanding precision applications like in the alignment of optical lenses to LED bars and the latest inkjet technologies. Our unique expertise in the dimensional metrology of cylinders combined with our precision engineering skills resulted in ground-braking levels of precision for Canon Production Printing, which could be used both in their R&D and in production.

“Coming together is a beginning, keeping together is progress, working together is success."

- Henri Ford