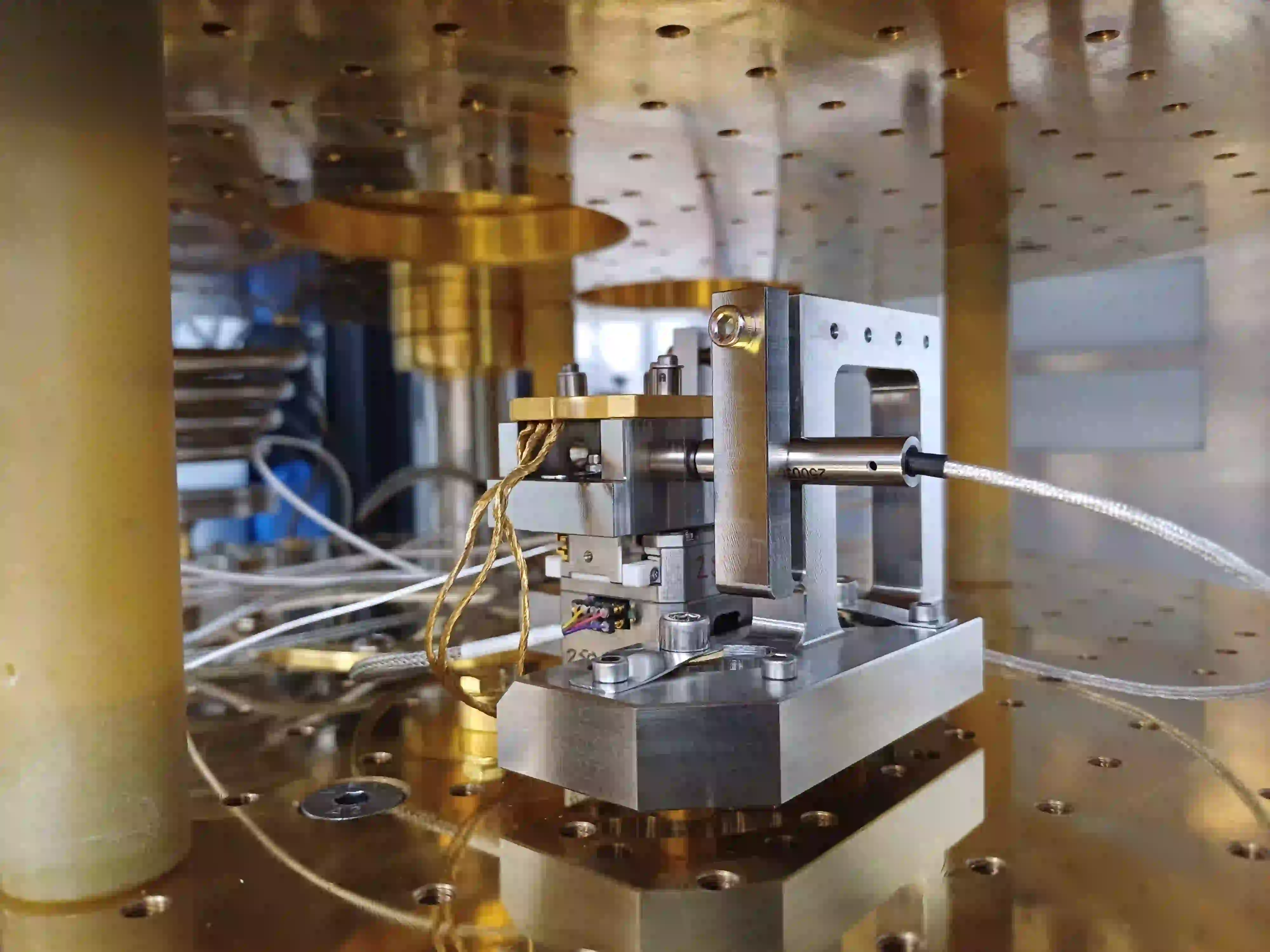

IBS presented at LOPEC the latest innovation in in-line interferometer solutions for areal surface measurements of micro and nanoscale structures, ideal for quality inspection of printed electronics in their production process. Combined with air bearing technology for non-contact flexible web guiding and stabilisation on roll-2-roll lines, these interferometry measurements can be done in under a second. Such in-line 3D metrology promises to revolutionise the production process by avoiding time consuming off-line measurements.

In-line Interferometry

ARINNA (Areal Interferometer for Nanoscale Surfaces) provides measurement data in under a second which can be used in-line to improve process and yield performance. Successful measurements can be achieved using ARINNA on a (semi-)transparent and low reflective web in a roll to roll line. By stabilizing the foil with air bearing technology, it is possible to measure features in the nanometer range. With the use of a dancer system the web can be buffered to a short stand-still, to create a measuring moment in which ARINNA can perform its under-a-second quality measurement.

Read more: In-line Interferometry for Precision in Roll-2-Roll production

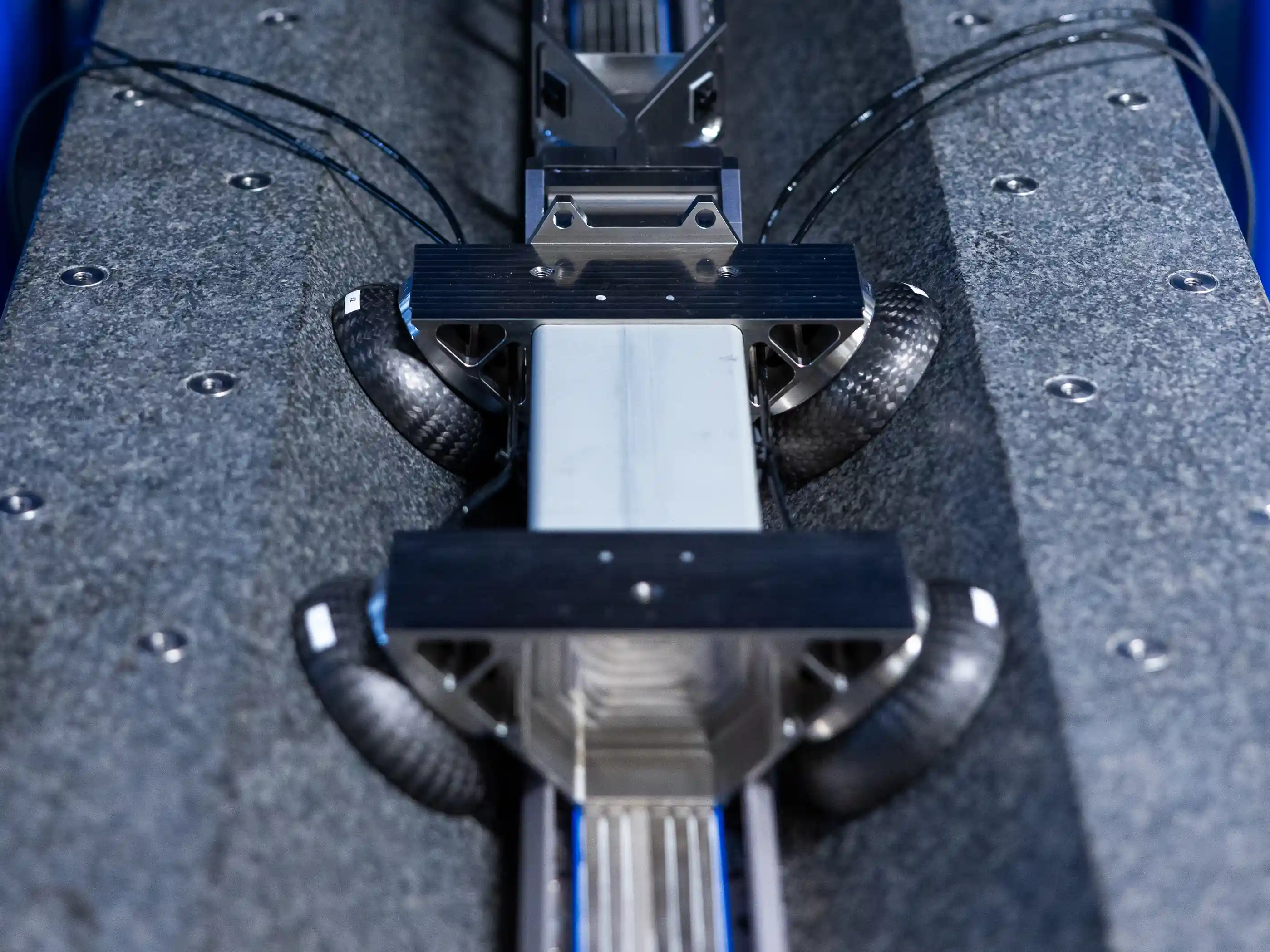

Contactless web handling, flattening and stabilisation:

Air bearings can provide high precision, non-contact guided movement for web handling. By avoiding contact between the web and the web handling equipment – e.g. transport rollers – they remove a major source of damage to sensitive webs. Air tables can be used to generate a very flat web, critical for printing, drying and inspection processes.

- Air Turns

Cylindrical porous-media air bearings, or air turns, can be used as replacement for idler rollers i.e. non-driving contact rollers, for web transport. A web can be wrapped over the air turn, in the same way as with a roller. The air layer between the non-rotating cylindrical air turn surface and the web allows frictionless motion as there is no physical contact. Air turns have been realized to support webs on a stiff < 0.1 mm air layer, proving the feasibility of contactless handling without losing web control.

- Air Tables

Conveyor air bearings, or air tables, normally used for transport of rigid substrates, may also be applied for web transport. In such air tables, vacuum grooves are used to pull the supported web towards the air bearing, improving stiffness and stability at a given fly height. To investigate how much the air tables reduce vibrations in a moving foil, the foil height can be measured. Tests show that without support by the air table, vibrations of more than 250 µm were seen in the foil. With the air table, these vibrations were reduced to < 5 μm.

Read more: Air Bearing Technologies For Roll-2-Roll Applications

We were delighted to speak to so many people in person again. Let's meet again next year, at LOPEC 2023!