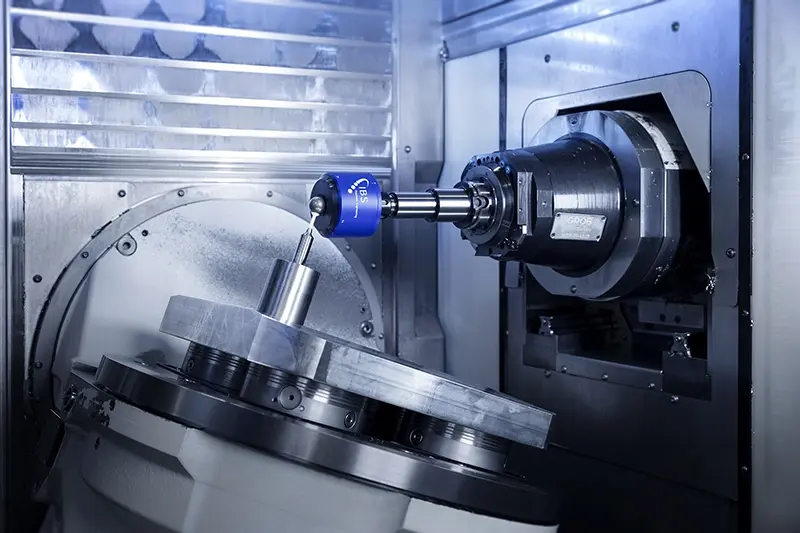

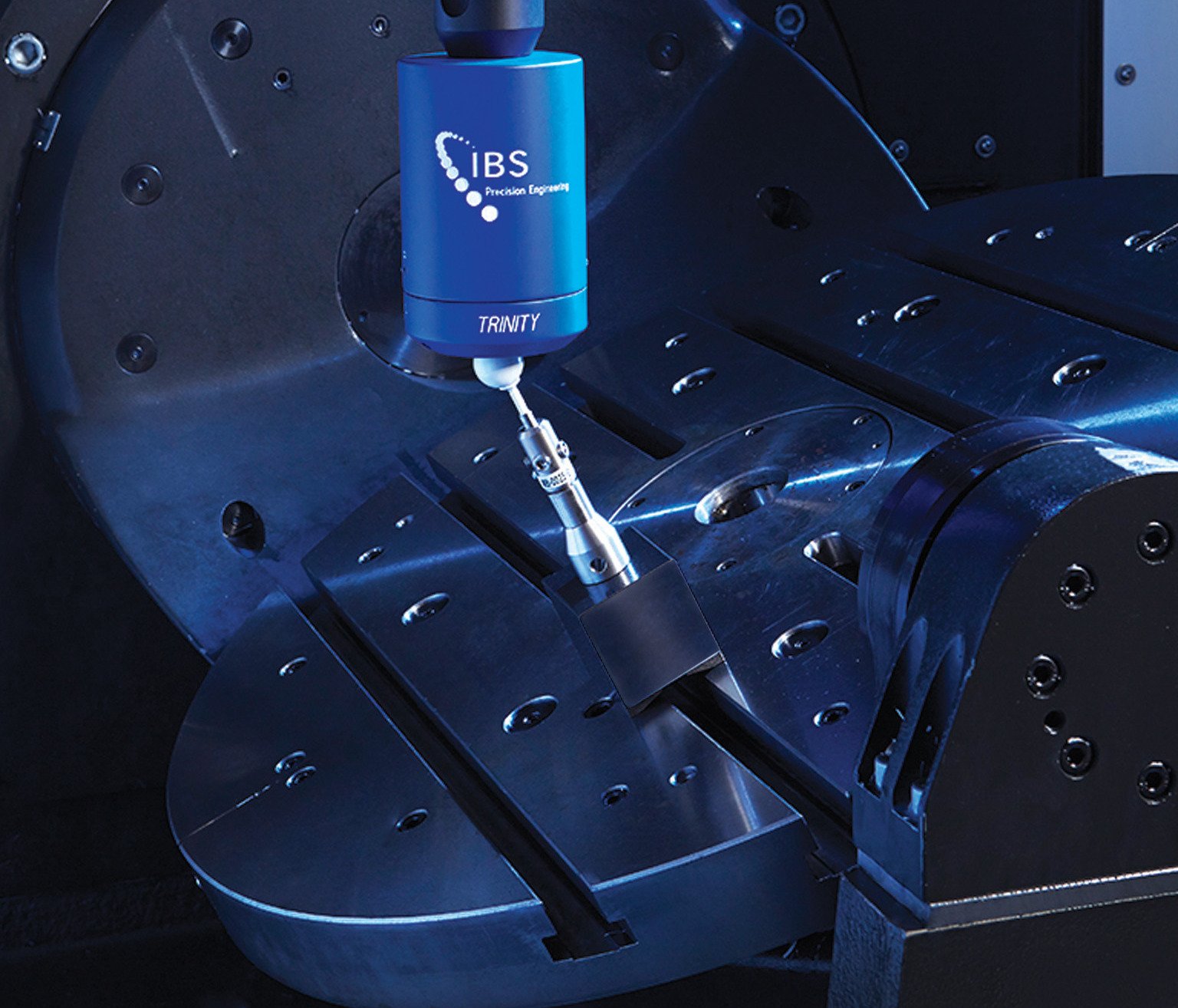

With its multi-axis PROKOS XT grinding machine, Blohm Jung simultaneously addresses complexity, flexibility and quality issues in modern manufacturing. For maintaining the machine’s volumetric accuracy of +/– 25 micron, Blohm Jung extended its volumetric compensation process, developed for conventional 5-axis machines, to a 6-axis version. IBS Precision Engineering helped them develop their procedure using the Rotary Inspector, a special wireless probe system, for measuring the three rotational axes. As Blohm Jung’s launching customer, MTU Aero Engines uses the compensation software for multiple PROKOS XT machines in the manufacturing of turbine components.

Open / Download the full article here. (Article published in CMM Magazine - January 2020 edition)