- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

- About IBS

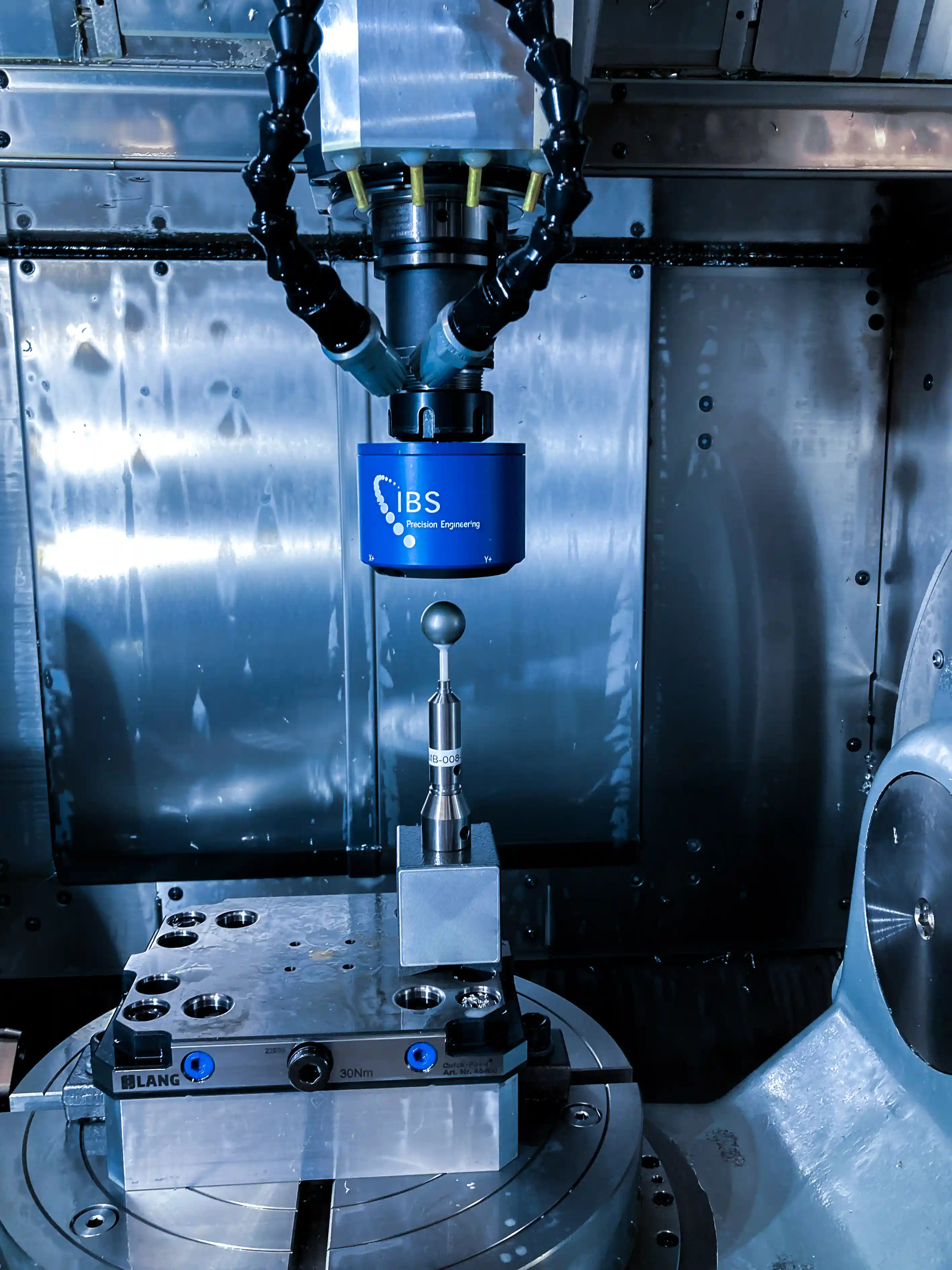

When you require precise measurement, rapid results and tangible improvements, our Machine Qualification product series can provide control by guaranteeing your machine is within specification.

Join us for an exclusive online webinar where we introduce you to our Machine Tool Qualification products to solve your precision challenges.

Qualifying the performance of 5-axis machines can be complex. We will introduce you to our newest addition to the catalog, the Trinitym. The perfect wireless tool for analyzing and diagnosing the volumetric and dynamic behavior of 5-axis machine tools with high resolution. Due to the reduced footprint of the probe, compared to the traditional Trinity, the Trinitym can be used in smaller machines. It also offers an increased accuracy.

The new software update for the Rotary Inspector system will be discussed as well. This update delivers an increase in speed and simplicity for linear and rotary axis measurement while maintaining traceable micron accuracy measurement to ISO standards. Also available for the traditional Trinity.

Automatic compensation is an option and one of the key features of our Rotary Inspector system. We can tell you how this can work for you.

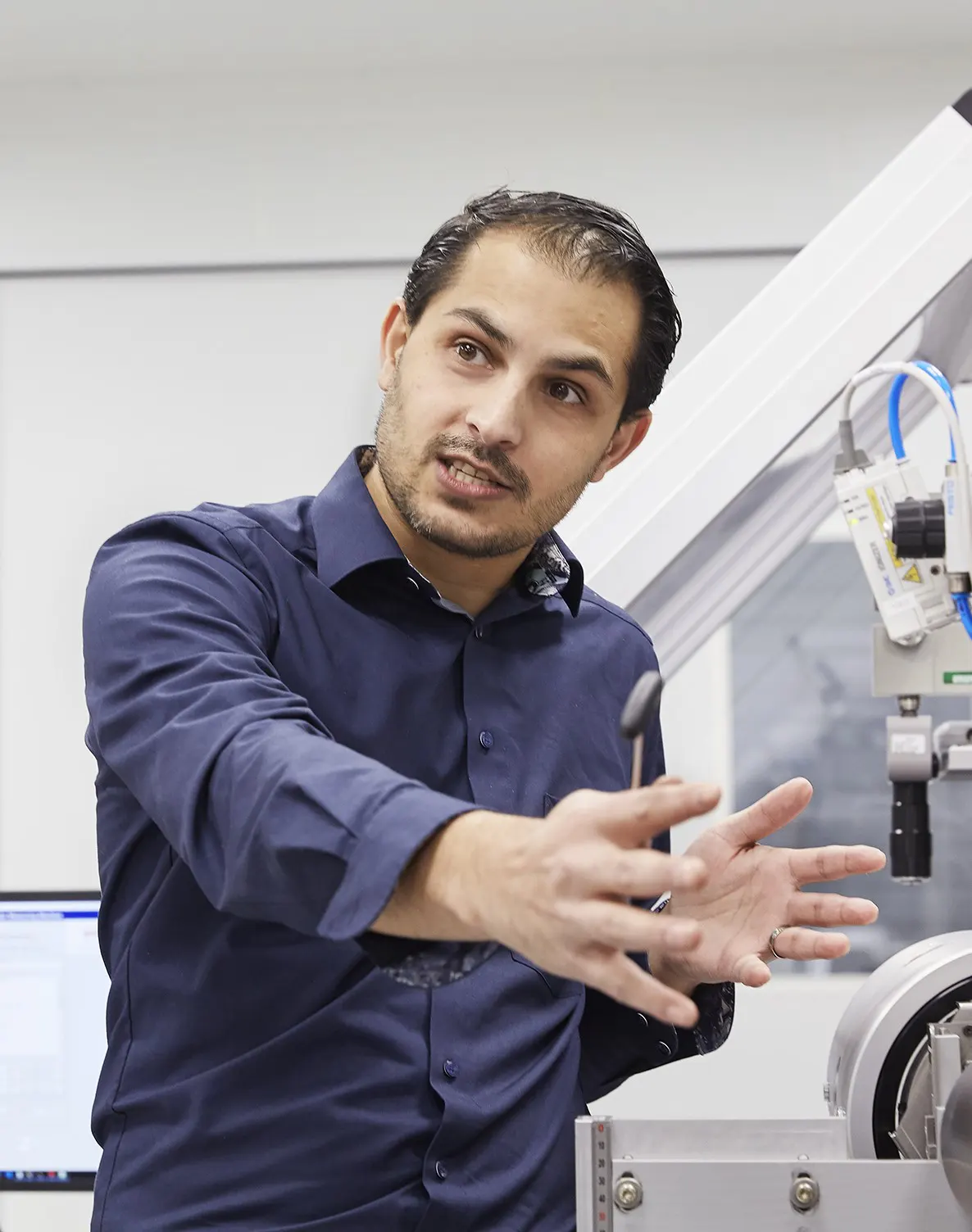

This webinar is for machine tool builders, maintenance providers and other advanced users of machines for high precision manufacturing.

Sign up now for free, and secure yourself a spot in the webinar.

Don't waste time with machine qualification methods that are complex to set up and take a lot of time to execute. Our solutions offer micron-level accuracy in just minutes. With options for measuring linear axis, rotary axis, and spindle accuracy, as well as compensation for linear and rotary axes, you can trust our products to provide unparalleled precision and speed. Effortlessly measure, control, and qualify the 3D dynamic movement of your machine, ensuring precise geometric behavior across the XYZ axes in a matter of minutes.

Ensuring that the machine is able to accurately move the workpiece to the correct position.

Ensures that the machine is able to accurately rotate the workpiece to the correct position.

Used to measure the amount of runout in the spindle, which can affect the accuracy of the finished part.

Calibrating cutting tools, such as end mills and drills, to ensure that they are accurately sized and shaped.

Testing the repeatability, by measuring the variation in position or measurement readings over multiple cycles.

Verifying the geometry of the machine tool, such as the squareness of the axes.

Ensuring that all components, such as the headstock and tailstock of a lathe, are parallel to each other and perpendicular to the workpiece.

Discovering problems, such as excessive vibration, chatter, or tool wear, by identifying any errors or inaccuracies in the machine's calibration.

Providing accurate data on machine tool performance and calibration to optimize tool paths for cutting operations, resulting in improved efficiency.

Monitoring the accuracy of a machine tool over time, and to schedule regular maintenance or recalibration as needed to ensure continued performance.